THERE ARE 4 ADVANTAGES OF USING VICTAULIC

COUPLINGS TO ACCOMMODATE PIPE MOVEMENT DUE TO

THERMAL CHANGES

Pipe design flexibility

Reduced stress on the piping system

A more compact, inspectable and productive method of installation over other pipe-joining methods such as welding

Conforms to industry practices in industrial building services

The key to effectively accommodating pipe thermal expansion and contraction in a building is to allow the predictable, controlled movement of the piping itself. This can be achieved in a variety of ways; the selection of a specific method is based upon the engineer, the type of piping system and the project parameters.

EXPANSION

CONTRACTION

4 WAYS GROOVED COUPLINGS ACCOMMODATE THERMAL MOVEMENT

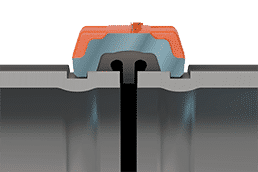

![]() They provide an expansion joint utilizing grooved

They provide an expansion joint utilizing grooved

mechanical pipe components.

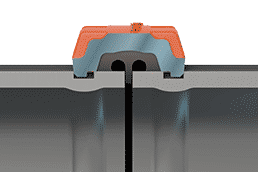

![]() They allow the system to “free-float”.

They allow the system to “free-float”.

![]()

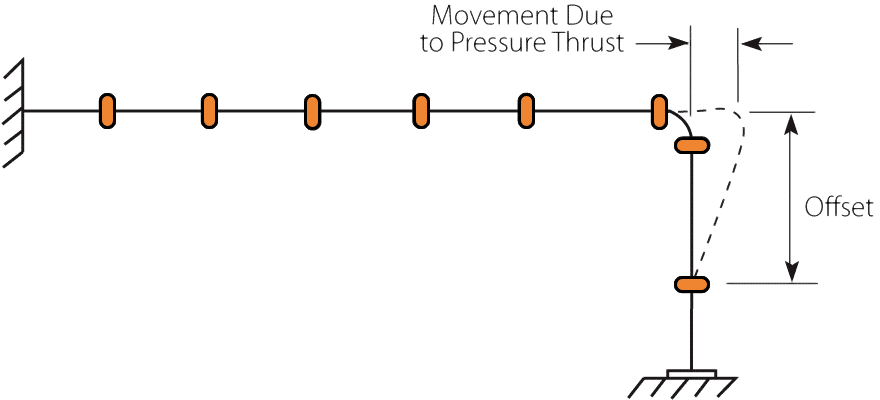

They utilize the linear movement/deflection

capabilities of flexible grooved couplings.

![]() They provide an expansion loop utilizing grooved

They provide an expansion loop utilizing grooved

mechanical components.

3 REASONS WHY GROOVED COUPLINGS ARE A SMART ALTERNATIVE

![]() Grooved pipe couplings are easier and faster to install over welding.

Grooved pipe couplings are easier and faster to install over welding.

![]() They accommodate movement within the design capability of the grooved coupling, and are done within the product’s "free range of motion.”

They accommodate movement within the design capability of the grooved coupling, and are done within the product’s "free range of motion.”

![]() Piping system movement caused by pipe thermal expansion and contraction can be accommodated in smaller spaces, with low stress on the components.

Piping system movement caused by pipe thermal expansion and contraction can be accommodated in smaller spaces, with low stress on the components.