Mechanical Pipe Joining Systems

Togetherness – that’s what our mechanical joining systems are about. Our Seals and Joining Technologies (whether grooved, press, plain-end or otherwise) together form the basis for our advanced products. All are manufactured to exacting standards and for optimal performance to satisfy your piping requirements.

GASKET/SEAL TECHNOLOGY

At the heart of our pipe joining products is the seal. That is why all of our gaskets/seals are subject to stringent quality control, precision engineering and exhaustive testing before they ever make it into our customers' hands. Why do we spend so much time on seal technology? Because failure is never an option.

HOW DO WE DO IT?

Using advanced element analysis, our staff of world class materials engineers are able to predict the performance of materials in numerous configurations and in countless field conditions.

We then back up that analysis with in field testing. In fact, years of this type of analysis and testing has led to the development of our own proprietary seal compounds such as the Victaulic Grade “EHP” EPDM Gasket.

The Victaulic Grade “EHP” EPDM Gasket is the only 250°F/121°C rated EPDM gasket on the market. That is a 20 degree increase in temperature from standard industry EPDMs (rated at 230°F/110°C). Our engineering customers know that an increase in temperature ratings for a gasket translates into increased confidence in their piping systems.

GROOVED TECHNOLOGY

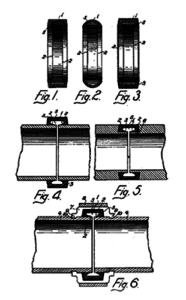

The concept of grooved technology, as it is known today, was born into existence in 1919 when Ernest Tribe, a British Royal Engineers Lieutenant and Dr. Henry Selby Hele-Shaw, a renowned engineer, finalized a patent application of the invention of the grooved mechanical coupling. Originally known as The Victory Pipe Joint Company, Victaulic began to market this revolutionary new concept in the pipe connector industry. Nearly 100 years later this technology continues to evolve and change the way the construction industry looks at piping systems. It's simply a faster, easier and safer way to join pipe.

So what is grooved technology?

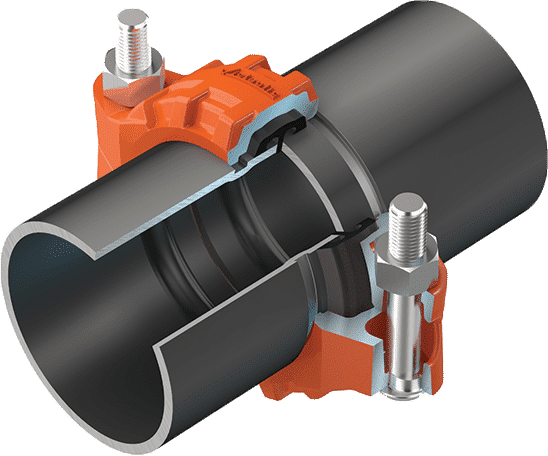

Grooved technology is the combination of four key elements:

- the grooved pipe

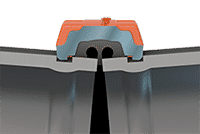

- the gasket

- the housings

- the nuts and bolts

These 3 components make up a grooved coupling.

How do grooved couplings work?

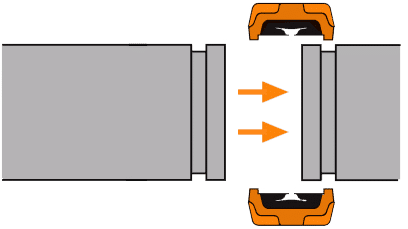

The pipe groove is made by forming or machining an actual groove into the ends of two pipes. A gasket wraps around and on top of the pipe ends, the housings wrap around the gasket and sit in the pipe grooves, and the bolts and nuts are tightened with a wrench to hold it all together.

There are two basic grooved coupling styles:

Flexible grooved couplings

These allow a limited amount of angular movement.

Rigid grooved couplings

These do not allow movement and can be used wherever immobility in the pipe joint is needed, similar to a flanged or welded joint.

Style 177N QuickVic™ Flexible Coupling

STYLE 107N QUICKVIC™ RIGID COUPLING

Today grooved couplings along with grooved fittings, grooved valves and grooved accessories (such as strainers and suction diffusers) are found in a seemingly endless number of piping applications worldwide.

While the grooved pipe joining concept has become synonymous with faster and easier installations, not all manufacturers of grooved products are the same. We are unique. There is only one Victaulic for reliable, durable, precision-constructed piping systems.