Revolutionizing Constructability With Modular Ductile Iron Piping

Victaulic is redefining how ductile iron systems are built. Our modular approach brings off-site precision, quality assurance, and schedule certainty to a market long reliant on traditional field assembly, delivering the same efficiency and consistency once reserved for carbon and stainless-steel systems.

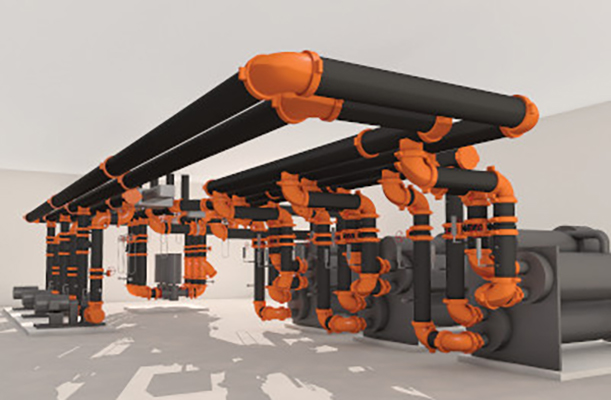

Modularization Capabilities

VDC

Victaulic's global VDC team utilizes BIM and Revit tools to design piping systems that minimize on-site assemblies, reduce installation time, and improve project schedules.

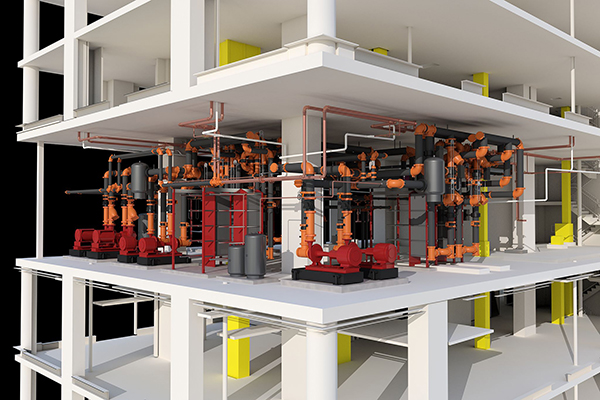

Off-Site Modularization

Piping systems are preassembled in controlled environments and delivered as modular units, reducing material handling and maximizing jobsite productivity.

IPD

Victaulic offers a full suite of Integrated Project Delivery (IPD) services, including BIM, estimation, preassembly, and field construction to assist with potential new projects.

Benefits

Faster Installation

Victaulic's grooved ductile iron systems install up to 10x faster than traditional flanged welding methods.

LABOR EFFICIENCY

Reduce on-site handling and eliminate loose fittings with preassembled spools.

Safety

Modular assemblies reduce loose fittings by up to 70%, ensuring fewer lifts, lighter assemblies, and less risk of injury.

QUALITY ASSURANCE

Every joint inspected and verified under controlled factory conditions.

SCHEDULE PERFORMANCE

Accelerate installs with site-ready solutions and just-in-time delivery.

MATERIAL MANAGEMENT

Bag-and-tag delivery services minimize misplaced materials and delays.

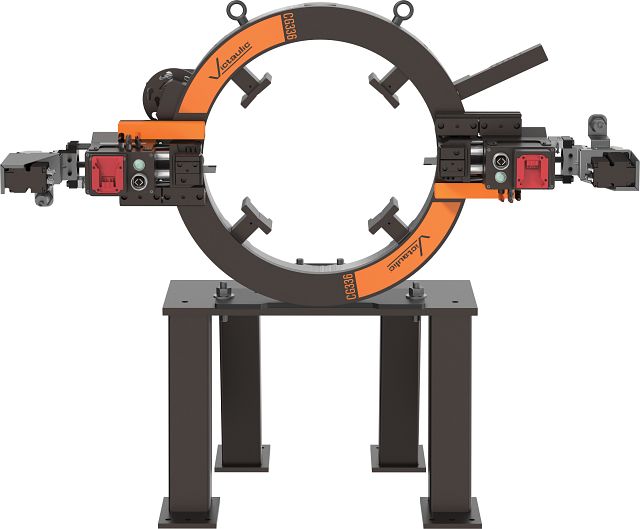

CG336 Portable Cut Grooving Tool

Victaulic’s CG336 Portable Cut Grooving Tool bridges design and installation, allowing contractors to cut and groove ductile iron pipe from 3" to 36" directly on site. This flexibility ensures seamless field adjustments on every project.

• Grooving Capability: 3-36″ AWWA ductile iron pipe

• Modular field fabrication cut grooving tool

• Designed to simultaneously square cut and groove ductile iron pipe ends

• Hands-free operation with auto-feed cutting and grooving bits and safety foot switch

• External mounting and drive action designed for use with all coating and lining types

Projects

Literature

| Resource | Number | Downloads | Collection |

|---|---|---|---|

| CG336 Portable Cut Grooving Tool Repair Parts | RP-CG336 |

|

|

| Virtual Design and Construction (VDC) | MB-105 |

|

|

| Radius Cut Groove Specifications (Rigid/Flexible) | 25.05 |

|

|

| Style 31 AWWA™ Coupling Submittal | 23.02 |

|

|

| AWWA (Cast) Fittings Submittal | 23.05 |

|

|

| Style 257C Dynamic Movement Joint Submittal | 23.17 |

|

|

| Series 365 (D.I. ENDS) AWWA Plug Valves Submittal | 23.06 |

|

|

| Series 317 AWWA Check Valve Submittal | 23.09 |

|

|

| Style 307 AWWA™ Transition Coupling Submittal | 23.03 |

|

|

| No. 326C AWWA Manifold Fitting Submittal | 23.23 |

|

|

| AWWA Field Installation Handbook | I-300 |

|

|

| AWWA Grooved System Design Data | 23.01 |

|

Content Library

View & download Victaulic content files for BIM piping software, including Autodesk - AutoCAD 2D, 3D Blocks & Plant 3D; Autodesk - Revit MEP; Autodesk - Fabrication CADmep; Bentley AutoPlant; CEA Systems - Plant 4D; Trimble - PipeDesigner 3D, DWG & more. Download available for individual files & full package zip files.

Request more information

Fill out the form below to connect with our product experts and receive more information, including availability, product specs, and how to purchase.