NOISE AND VIBRATION ATTENUATION

IT CAN BE DONE WITH GROOVED TECHNOLOGY AND HERE IS HOW AND WHY YOU WANT TO USE IT.

Mechanical room equipment creates noise and vibration

in a piping system, which can be difficult to contain.

Designers can specify the use of Victaulic couplings

to isolate this vibration.

In addition, Victaulic flexible couplings will also accommodate for misalignment, reduce stress on

pumps and equipment connections, and

accommodate linear movement and angular

deflection in a piping system.

HOW DO VICTAULIC COUPLINGS DAMPEN NOISE AND VIBRATION?

The unique construction of our grooved coupling enables the gasket to seal against pipe, while the housing provides both space for the seal to flex and containment to prevent overstretching. Our couplings work to create a permanent leak-tight seal, with no need for additional reinforcement. Additionally, ductile iron also absorbs sound.

AS A REMINDER, THERE ARE TWO BASIC GROOVED COUPLING STYLES:

- Flexible grooved couplings - These allow a limited amount of angular movement.

- Rigid grooved couplings - These do not allow movement and can be used wherever immobility in the pipe joint is

needed, similar to a flanged or welded joint.

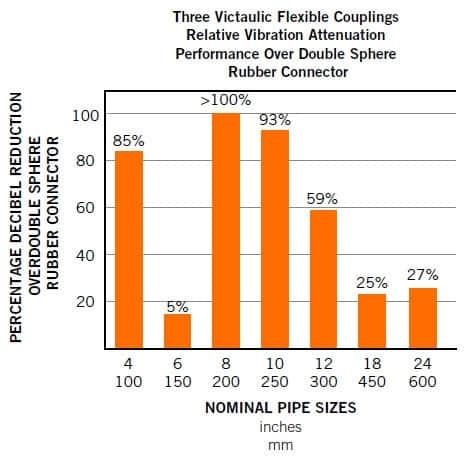

IS THERE PROOF VICTAULIC GROOVED REDUCE PIPE VIBRATION?

Yes! In 2013, Victaulic completed testing

at NASA's Vibration and Acoustic Test

Facility (VATF). The results showed that

the vibration attenuation provided by

three (3) Victaulic flexible couplings,

installed near the source of vibration,

outperformed the double sphere rubber

connectors and stainless steel braided

pump connectors.