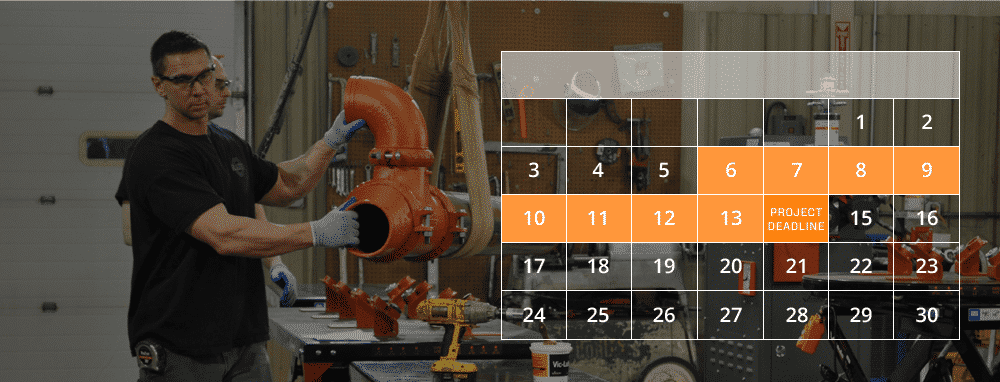

COMPRESSED CONSTRUCTION SCHEDULES

Victaulic grooved pipe joining is up to ten times faster than traditional pipe joining methods, such as welding, threading, fusing, and soldering.

WHAT IS A GROOVED PIPING SYSTEM?

A grooved piping system is a fast, clean, safe, and dependable way of joining pipe as opposed to welding, threading, flanging and soldering. Traditionally, grooves are rolled or cut into the ends of the pipe on the job or in the fab shop while fittings, valves and other components are manufactured with the same groove profiles. Until recently, the pipe, fittings and other piping components were all joined using grooved mechanical couplings. Click here for more information on Victaulic's Grooved Technology

Now, with the introduction of Victaulic's Installation-Ready™ line of fittings, in some applications, pipe can be joined with just a fitting. See Victaulic's line of Installation-Ready™ fittings for Copper or our FireLock™ Installation-Ready™ fittings.

WHAT IS THE TIME OF INSTALLATION USING GROOVED COUPLINGS VS. WELDING?

While standard grooved pipe couplings install 5 times faster than welded joints and 3 times faster than flanging, Victaulic's grooved piping products install up to 10 times faster than other pipe joining methods. The speed and ease of installation that Victaulic provides to its customers stem from nearly 100 years of innovation and customer research. The patented Installation-Ready product line is a perfect example of how Victaulic is committed to designing, developing and providing our customers with products that target our customers' need to compress their project schedules saving them time in the field and money on the bottom line.