Oyu Tolgoi (OT) Mine Project

- Accommodating for Angular Deflection

- Accommodating for Movement

- Coordinated Delivery

- Sustainability

- Training

- Carbon Steel

- Carbon Steel - Galvanized

- HDPE

- Accommodate for Thermal Movement

- Compressed Construction Schedule

- Corrosion Resistance

- Ease of Installation

- Improved Safety

- On-site Training & Support

- Reliability

- Simplified System Maintenance

- Sustainability

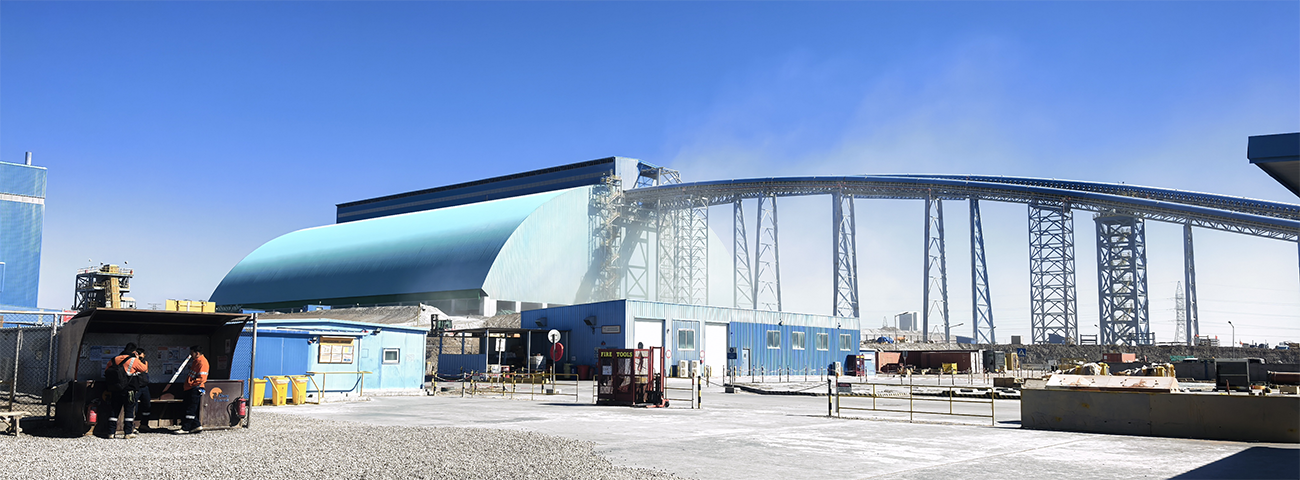

The Oyu Tolgoi (OT) mine, located in Khanbogd sum in Mongolia’s South Gobi Desert, is one of the world’s largest known copper and gold deposits. As a combined open-pit and underground mining operation, OT is internationally recognized for its advanced technology, high safety standards, and commitment to sustainable development.

From the early stages of project planning, the owners and engineering teams placed a strong emphasis on the reliability and quality of the process piping systems. Victaulic’s mechanical pipe-joining solutions were selected as the preferred technology due to their proven performance in demanding industrial environments. The grooved piping system offered significant advantages, including faster installation, easy maintenance, labor and cost savings, and enhanced jobsite safety. With a union at every joint, the system allows easy access for routine inspections and servicing, minimizing downtime and improving operational efficiency.

Trusted by OT since 2007, Victaulic solutions are still going strong after 16+ years. They have been deployed across multiple critical systems, covering pipe sizes from ¼ to over 24”, including the slurry transportation system, pastefill system, compressed air system, fire protection water system, and tailings transportation pipeline. Each system presented unique engineering challenges, which Victaulic solutions helped overcome.

In areas with limited space and restricted access, mechanical grooved couplings such as Style 77 and Style 07 enabled installation without the need for welding—an approach that would have been extremely difficult or even impossible in such conditions. As a cold-formed joint, Victaulic couplings eliminate the need for open flames or hot work, significantly improving safety during installation. On suspended piping frames, Style 995 couplings for HDPE plain-end pipe were used to reduce installation time and facilitate easier access during scheduled maintenance.

The harsh climate of the South Gobi Desert posed additional challenges, particularly in managing large temperature fluctuations. Victaulic’s flexible couplings provided an effective solution by accommodating thermal expansion and contraction, ensuring the integrity and longevity of the piping systems.

Victaulic’s grooved piping technology has consistently delivered value to the OT project, both in design and execution. By addressing key concerns such as space constraints, thermal movement, and maintenance accessibility, the system has helped achieve up to 50% savings in installation time and cost. This long-standing partnership underscores Victaulic’s commitment to supporting safe, efficient, and sustainable mining operations in some of the world’s most demanding environments.