Posted on October 22nd, 2025

According to Autodesk and FMI, nearly 52% of all rework in construction is due to insufficient project data and poor communication. With tighter schedules and margins under pressure, contractors are looking for ways to gain better control over their operations.

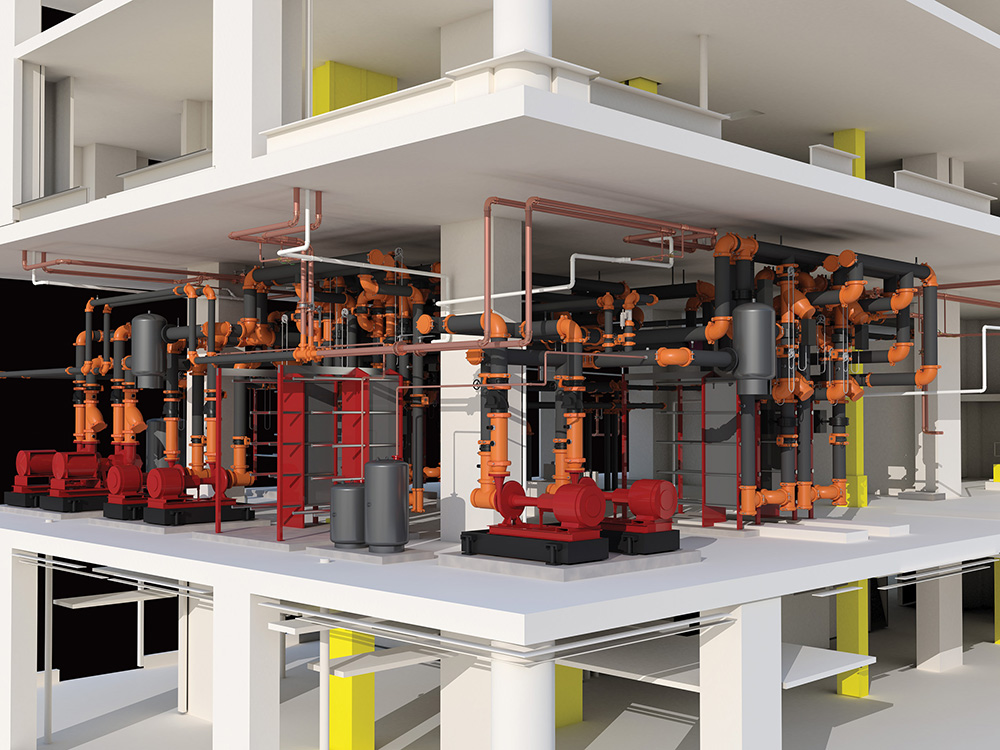

One way they’re doing this is by establishing in-house fabrication shops that enable their teams to increase efficiency and free up resources to take on additional projects. However, simply having a fabrication shop doesn’t guarantee better operational control. The true secret to optimization is pairing fab shop capabilities with standardized fabrication-ready design practices.

Digital tools can further enhance these standardization efforts. Victaulic Tools for Revit® (VTFR), an add-in for Autodesk’s Revit that automates intelligent routing within the building information model, helps catch design errors during the modeling phase before they become expensive shop mistakes. The Victaulic SpoolTracker App, a free mobile app that provides real-time visibility into spool locations and status through QR code tracking, tracks actual performance during fabrication and enables clear, documented communication between the fabrication shop and field teams. The SpoolTracker App integrates with VTFR so when designers make changes to the Revit model, fabrication teams can immediately access updated information.

Building predictable, repeatable processes that streamline production ensure contractors can take advantage of the benefits of a fully optimized fabrication process and will be crucial to achieving a firm’s goals.

Shop-Built vs. Stick-Built Projects

Construction sites are inherently uncontrolled environments, with field conditions constantly in flux— from environmental to human factors. While adapting to changing conditions is a valuable skillset for contractors, these variables can make or break projects with tight schedules and budgets. Fabrication shops enable contractors to mitigate these variables, providing the schedule and cost certainty many projects demand.

Shop floors offer consistent lighting, climate control and bench-height surfaces that enable contractors to work more efficiently and precisely compared to cramped mechanical rooms or weather-impacted outdoor job sites. Shop-built spools reduce the volume of field joints teams must perform, allowing them to move efficiently from area to area and complete installations faster. Pipe spools, assemblies and other components built in the shop arrive ready to install, reducing the rate of field interpretations and adjustments that can trigger rework in later project stages.

3 Ways to Optimize Pipe Fabrication Shop Operations

Standardization transforms fabrication from a custom process into a predictable and efficient operation. However, optimizing processes doesn’t mandate a complete overhaul. Teams can start by implementing three small — but essential — design practices.

Method 1: Standardize Pipe Spool Dimensions

A good place to start integrating fabrication-ready design is by rounding measurements and pipe lengths to consistent dimensions.

Establishing standard pipe sizes enables fab shops to batch similar cutting operations, reducing machine setup time and improving workflow efficiency. Standard lengths also optimize transportation by stacking more efficiently in delivery trucks and simplify field installation by allowing crews to work systematically through one size before moving to the next.

Manual standardization across multiple projects can be time-consuming and inconsistent. For teams who want to implement standardization practices, VTFR can assist by helping designers to standardize lengths and suggesting appropriate fittings for each application.

Method 2: Standardize Equipment Configurations

Pump, chiller and air handler connections typically require multiple components, including isolation valves, check valves, pressure gauges, flexible connectors and engineered supports. Creating standard templates for these configurations reduces design time and eliminates field interpretation. Often, the same pump connection design can be replicated in hospitals, office buildings and schools, helping fabricators develop efficient assembly techniques while repeatability allows field crews to hone their craft to reduce installation errors and callbacks.

The Victaulic SpoolTracker App helps contractors evaluate which standard equipment configurations perform best over time. Teams can photograph spools at each stage to document quality issues and track fabrication times for different connection types in the shop, providing data to refine standard workflows based on actual performance.

Method 3: Implement Production Cycles

Fabrication teams can reduce changeover time to maximize shop efficiency by organizing work into structured production cycles. Switching between pipe sizes requires resetting fabrication stations, and these changes can disrupt workflow momentum by adding 30-60 minutes of reconfiguration time. Batching by size allows shops to complete quality control checks on size-specific standards each day while maintaining a steady workflow. Shops can adjust the timeline based on their capacity and project requirements.

Digital tools can enhance tracking and quality control throughout these production cycles. The Victaulic SpoolTracker App has dashboard features that show the status of each spool by tracking QR code scans at each stage, allowing fab shop managers and project managers in the field to see which spools are in cutting, grooving or assembly phases and spot delays early. This feature also provides the most recent location for each spool, ensuring that assemblies aren’t misplaced on site. The SpoolTracker App is also integrated within VTFR which helps to address communication gaps between design and fabrication teams. When designers make changes to a Revit model, they have the option to push that data to SpoolTracker so fabrication teams can easily access updated information.

What Contractors Save by Standardizing Pipe Fabrication

Standardizing pipe fabrication delivers measurable improvements across shop operations and job site performance.

VTFR and the Victaulic SpoolTracker App support these standardization efforts by connecting design and fabrication workflows. With each completed project, the use of the SpoolTracker App provides data-driven insights to improve shop-build and standardization methods, improving operations over time.

Visit victaulicsoftware.com to explore how VTFR and the SpoolTracker App can help contractors implement these standardization methods on their next project.