An Automotive Component Plant Project

- BIM Coordination

- Fabrication

- Virtual Design & Construction

- Carbon Steel

- Compressed Construction Schedule

- Construction Modularization

- Ease of Installation

- Simplified System Maintenance

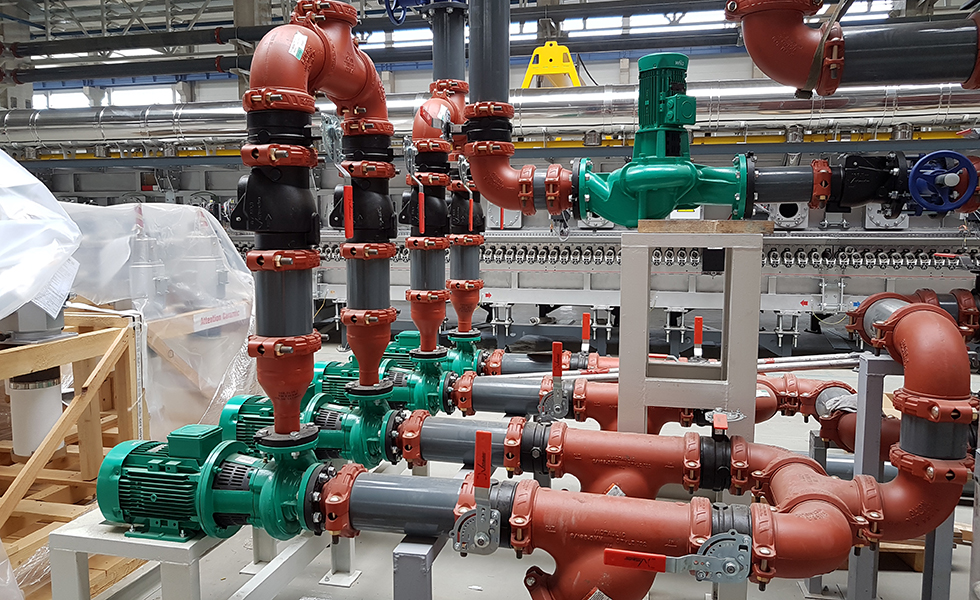

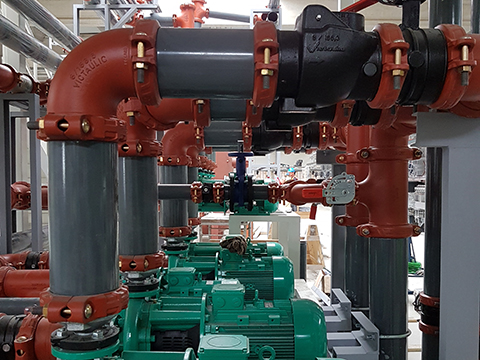

In 2017, a new automotive component plant was built in the Czech Republic, featuring an industrial cooling system that allows for car bodies to be set in the required form, after being ‘baked’ in hot-forming ovens. The site covers an area of 130,000 square meters, with 23,000 square meters being used as shop floor for the first production phase. To support the company’s bold ambitions, the owner of the plant contracted and tasked ČEZ Energetické služby to install the cooling system while working on very tight deadlines. The contractor knew right away that traditional, time-consuming pipe joining methods, like welding and flanging, were not up to the challenge, hence partnering with Victaulic, whose grooved products help to enable a fast and reliable pipe installation, became the evident solution to make the project a success. In total, ČEZ Energetické služby installed 3,400 Victaulic products in the cooling system, including couplings, valves, Mechanical-T outlets and fittings. These ranged in sizes from DN80 up to DN350.

At the new component plant, BIM-enabling technology allowed the designers, as well as ČEZ Energetické služby, Victaulic and other parties to visualize, monitor and update project design using 3D modeling. This improved collaboration at the planning stage and resulted in even less time spent installing the system on site. By applying this technology, Victaulic prepared a 3D model of the cooling system, which compartmentalizes the design of the system in various zones, so that it can be visualized in more granular detail. These granular 3D drawings demonstrated where each product was required and how they would be built on site, with all components in situ. The latest 3D technology offers an even more well-rounded experience by adding a virtual reality (VR) perspective to the design process. Ahead of construction, contractors, designers and customers alike can be taken on a virtual walk-through of the installed system, facilitated by the newest VR equipment.

When looking for opportunities to achieve further installation time savings, many contractors still overlook the possibility of prefabricating components off site. Common practice in the construction industry often prescribes products to be delivered at the beginning of a project. As such, spools are assembled on site, which can be tricky work, due to the processes it involves, including searching and preparing the correct amount of material for the specified work zone. That is why Victaulic recommends fabricating parts of the system upfront, whereby pipes are prepared and preassembled in the required quantities. For this particular project, for example, 1 and 2-meter long grooved pump drops were delivered ready for installation, helping to speed up the process and avoid uncertainties associated to weather that other pipe joining methods such as welding, for example, are heavily dependent on.

Given the continuous reimagining and development of technology, the cooling system at the new component plant is future-ready and prepared to be expanded or rerouted at any point in time. The usage of grooved solutions means that an entire installed piping system can be disassembled and remodeled, or fittings can be interchanged. Easy access to the system also makes the maintenance of grooved piping systems quick and cost-effective. Unlike a welded system, grooved solutions avoid maintenance costs associated to cutting out sections of pipe and extensive preparation necessary for rewelding. Choosing grooved solutions ultimately reduce system downtime too as it can be re-installed three to four times faster than a welded system.

External Links:

Pipe Joining: Quality on Time, ACR Journal