Clara Maass Medical Center Project

- Coordinated Delivery

- Carbon Steel

¼ - 2" / DN8 – DN50, 2 – 12" / DN50 - DN300

- Compressed Construction Schedule

- Confined Space Installation

- Cost and Schedule Certainty

- Design Flexibility

- Ease of Installation

- Fire Suppression

- Improved Safety

- Retrofit

When Clara Maass Medical Center embarked on a project to upgrade the fire protection system throughout its six-story, 472-bed medical center, the owner’s directive was clear: get in and out as fast as possible. The medical center serves Essex, Hudson, Passaic and Bergen counties in New Jersey as a Primary Stroke Center with nationally recognized programs in cardiac care and emergency medicine. Fast Response Fire Protection needed to bring the medical center’s sprinkler system up to code by installing 1,500+ sprinkler heads across an expansive campus with minimal disruption to the medical center’s active operation.

The medical center’s compartmentalized layout required 12 separate risers to feed the new system — a drastic change from its original system, which used just one or two risers. New piping had to snake through ceiling spaces already packed with ductwork, electrical systems and medical gas lines, often with just inches of clearance. The Fast Response team needed work in sections, remove ceiling tiles to access work areas, complete installations within short time windows and restore the space before moving to the next area.

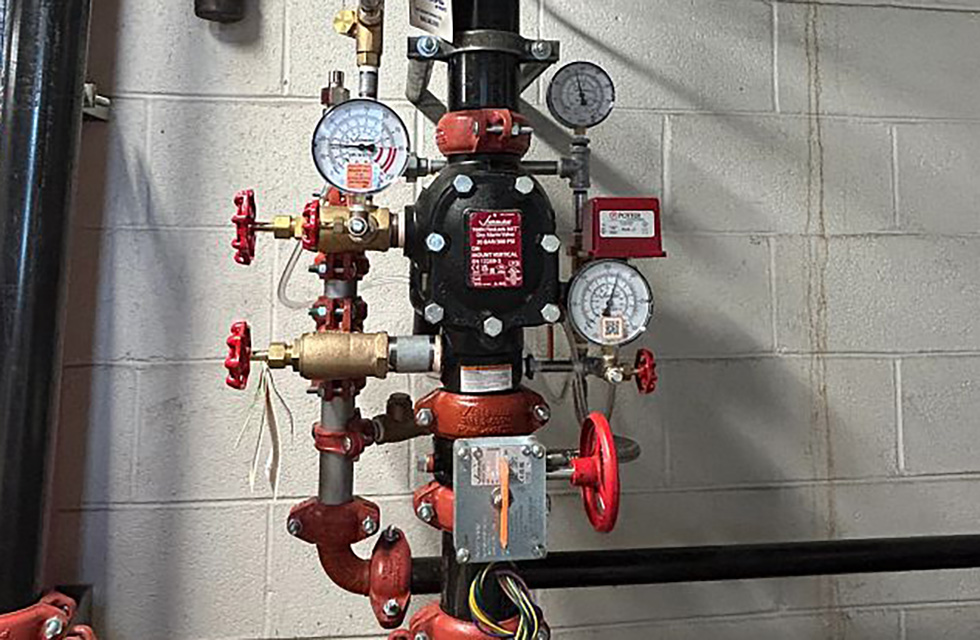

Fast Response partnered with Victaulic to implement solutions that addressed each retrofit challenge. The contractor installed 15 Series UMC Universal Manifold Check Assemblies (UMCs), placing them in a valve room and various stairwells to create separate floor zones in the six-story building. Each UMC arrived on-site complete with a control valve, check valve, flow switch, adjustable relief valve, flexible drain hose, gauges and test and drain, sparing the contractor’s team from a time-intensive on-site assembly of individual components.

Fast Response leveraged the advantages of VicFlex™ Series AH2-CC Braided Hoses in the crowded ceilings to maneuver around medical gas lines, electrical conduits and HVAC ducts. Without the flexible technology, the crew would need to hard-pipe sprinkler heads to ceiling tile centers — cutting pipes to exact lengths and offsetting around ceiling obstacles with additional fittings. By using VicFlex™, Fast Response could run the main water distribution pipes, and simply fasten the flexible sprinkler drops down into brackets in the existing ceiling tiles. No precise field measurements, no additional pipe-cutting and no threading required.

FireLock™ IGS™Installation-Ready™ couplings and fittings streamlined material handling and installation throughout the hospital’s small-diameter piping network. The single-bolt technology increased installation efficiency and eliminated the need to transport threaded components from remote staging areas back through active hospital spaces. Crews could feed the grooved prefabricated pipe into the ceiling and start making connections immediately, reducing material handling time and avoiding the disruption that threading mess and noise would cause to patients and medical staff.

For specialized areas, Fast Response used targeted solutions based on the specific protection needs. In the medical center’s kitchen, VicFlex™ Style AB6 assemblies protected the walk-in freezer and refrigerator. The AB6 brackets allowed for single-person installation from above the cooler, reducing the measuring, pipe preparation and sealing required with alternative dry sprinkler methods. The contractor used a FireLock NXT™ 768N Dry System Check Valve to protect outdoor spaces like loading docks and ambulance bays. By utilizing the convenient sprinkler assemblies and pre-trimmed valve, Fast Response ensured their critical project needs of timely installation and dependable fire protection were met.

The project required 2.5 years of phased construction to deliver critical fire protection to the expansive hospital, all completed without stopping patient care. The Clara Maass project is on track to reach completion in early 2026.