Ellume Health

- Carbon Steel

- Compressed Construction Schedule

- Cost and Schedule Certainty

- Ease of Installation

- Improved Safety

- Reliability

With the COVID-19 pandemic in full swing, the U.S. Department of Defense (DoD) awarded Ellume Health a government contract in 2021 to build a new production facility where the Australian company would help improve public health and safety by manufacturing at-home COVID-19 tests.

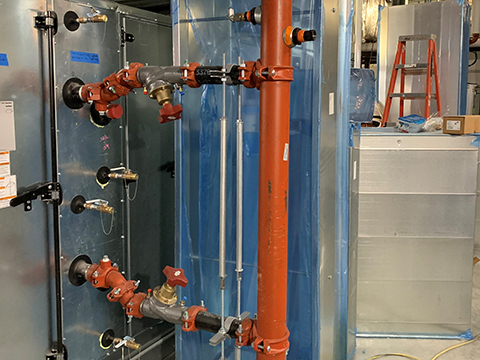

The contractor, Warner Mechanical, Inc., faced an extremely tight installation schedule for the 180,745-square-foot facility’s plumbing and mechanical systems. To meet the DoD’s requirements, Building A, where production would occur, needed to be completed and operational within 26 weeks. The design specified 12,791 linear feet of 2 ½- to 8-inch piping and included 1,530 tons of chilled water, 6,720 MBH of heating water, and 4,218 GPM of pump capacity.

Warner Mechanical’s success utilizing Victaulic to meet tight installation schedules in a previous pharmaceutical manufacturing project led the contractor to partner with the grooved pipe-joining solutions manufacturer once again.

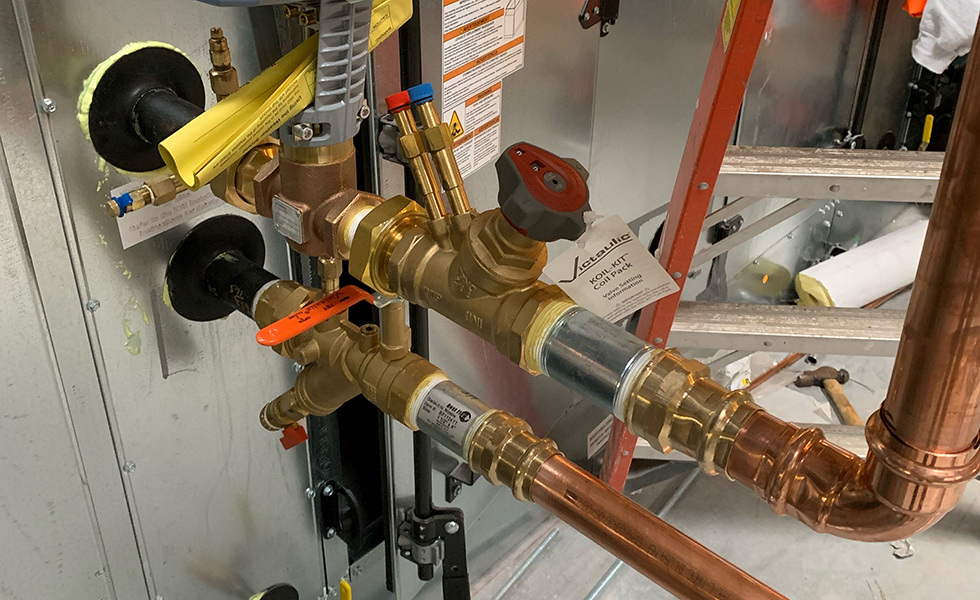

Victaulic couplings, fittings, and valves were used to join pipes throughout the system. The grooved methodology’s simple installation, combined with a crew that was previously trained in using the grooved technology, allowed Warner Mechanical to expedite installation. Victaulic pump drops, air handling unit drops, coil packs and other modular products also decreased the number of joint union assemblies in the system, further improving installation efficiency. Once Victaulic delivered the products, the contractor was able to prepare, assemble and install the entire mechanical system in three weeks while experiencing labor savings.