Fort McMurray First Nations Pump Station

- Fabrication

- Virtual Design & Construction

- Stainless Steel

- Compressed Construction Schedule

- Ease of Installation

- Simplified System Maintenance

The Fort McMurray #468 First Nation Pump Station was constructed in the summer of 2021 as part of a broader infrastructure plan to provide clean drinking water and sewage services for 600 residents of the Fort McMurray #468 First Nation reserve.

The project comprised of a new potable water reservoir and pumping station, new water distribution piping, new sewage collection piping, a retrofitted sewage lift station, and a new sewage force main to connect to the Regional Municipality of Wood Buffalo (RMWB) sewage system.

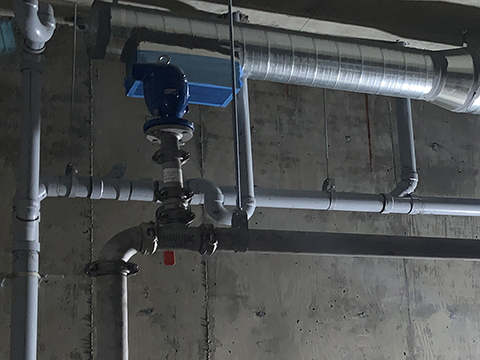

Victaulic partnered to provide a complete solutions package, including project modeling and fabricating; of the 3/4” (DN20) – 12” (DN300) above ground piping system. This system was connected to four pumps that were installed on the site. A variety of flow control solutions were also incorporated including Victaulic Series 970N Hydraulic Control Valves, Series 461 Vic-300 Stainless Steel Butterfly Valves, and Series 461 Vic-300 Two-way actuated stainless steel butterfly valves.

Expanding on 3D design completed by the engineer, Victaulic Virtual Design and Construction (VDC) created a complete drawing package, including 3D models and fabrication spools. The package was continually shared with the mechanical subcontractor, Goldbar, via video conferencing to work through the installation process and to identify any assembly issues prior to the installation. Over 250 couplings were assembled on more than 50 prefabricated spools and delivered to the site with everything tagged and labeled for ease of installation. Piping assemblies were fabricated in Victaulic’s Edmonton facility and delivered to the site for onsite installation.

The design and ease of installation of Victaulic products enabled Goldbar to install a majority of the piping in 3 days with only a two-person crew. This significantly minimized the overall project timeline and helped made up for some of the schedule delays that were incurred at the start of the project.

The project engineer, McElhanney, was also impressed with Victaulic’s solutions and the product’s ease of disassembly and reassembly for future maintenance. According to McElhanney, “The stainless steel system designed by Victaulic was not only constructed in a short span of time but also visually pleasing on the eye. This project was important to the First Nations community and will provide them with long-lasting benefits in years to come.”

External Link