HDPE System Installed at Saltwater Disposal & Mineral Water Injection Facility

- Coordinated Delivery

- Fabrication

- Training

- Virtual Design & Construction

- HDPE

- Compressed Construction Schedule

- Ease of Installation

- On-site Training & Support

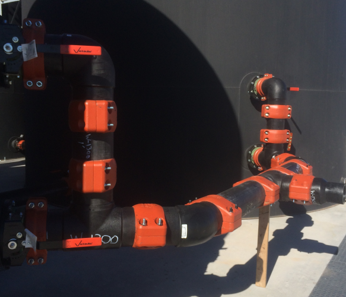

HDPE piping systems can be found throughout a variety of systems within Saltwater Disposal (SWD) facilities. The use of plastic pipe reduces corrosion and maintenance, with additional installation and maintenance benefits if Victaulic system solutions are employed. An owner in the Permian Basin realized these benefits on the construction of a new SWD facility. Looking for a quick and cost-effective solution to their previously fused HDPE piping system, the owner chose to partner with Victaulic for vertically integrated fabrication solutions.

Victaulic’s in-house modeling team worked hand-in-hand with the customer to design the SWD and mineral water injection facility. Upon design completion, spool drawings were developed and handed over to a Victaulic fabrication facility for spool construction. Fabricated spools were shipped to the site to meet the customer’s condensed project schedule.

The Victaulic HDPE system was installed in 3 weeks; 11 weeks earlier than originally anticipated. This substantial schedule reduction saved the customer upwards of $300,000 in labor cost and lost revenue.

Partnering with Victaulic enabled the project owner to maximize onsite productivity, mitigate risk, and reduce total installed costs.