Hines Texas Tower Project

- Accommodating for Movement

- BIM Coordination

- Project Modeling

- Virtual Design & Construction

- Compressed Construction Schedule

- Confined Space Installation

- Cost and Schedule Certainty

- Design Flexibility

- Ease of Installation

- Minimized Footprint

- On-site Training & Support

- Simplified System Maintenance

When Way Engineering, Ltd. was tasked with designing and installing the HVAC system for Hines’ Texas Tower, a 47-story, 1.14-million-square-foot high-rise office tower in Houston, TX, they knew they needed more than just a vendor, and turned to Victaulic to serve as a total project partner.

“Victaulic partners with you in a way that’s more than a vendor selling a catalog number,” said Derrick Williams, Executive Vice President of Operations at Way Engineering. “They partner with you to make the job a success and take an interest in the project, not just an interest in the sale of a product.”

Way Engineering’s decision to bring on Victaulic in the early stages of the project allowed for the partners to collaborate closely on engineering, planning and scheduling, anticipating potential challenges upfront. Despite limited staging and storage areas due to the high rise’s bustling downtown location, Victaulic helped seamlessly navigate these obstacles by coordinating bag-and-tag deliveries based on the project’s advanced bill of material, which kept the jobsite organized and significantly reduced lead time from four to eight weeks to just two to three days.

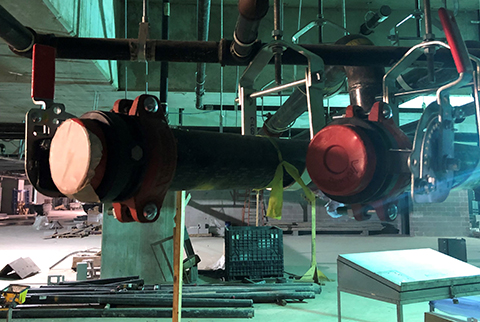

The project scope included four chillers, four cooling towers, 12 pumps, two heat exchangers, fans, filtration systems, duct systems, piping up to a 20” diameter throughout the building to serve the air handling units (AHUs), and risers from the basement to the cooling towers. To address the project’s pressure requirement up to 300 psi | 2068 kPa, critically important to system performance in a high-rise building like Texas Tower, they leveraged Victaulic’s Series 761 Vic-300™ MasterSeal™ Butterfly Valves which eliminated the need for a specialty valve, addressed pressure requirements and resulted in cost savings.

During installation, Victaulic helped Way Engineering overcome logistical obstacles including COVID-19 limitations around the number of people allowed on the jobsite, and the availability of just one service elevator that needed to be shared by all trades. Mobility, ease of installation and the ability for Way Engineering to prefabricate spool pieces before they made their way to the jobsite were critical advantages of the Victaulic solutions used on the project. It also reduced the number of connections required in the field, enabling Way Engineering to optimize onsite labor and adhere to COVID-19 restrictions.

Victaulic worked with Way Engineering throughout each phase of the project from engineering to planning, scheduling and installation. Despite pandemic-associated challenges and minimal staging and storage areas, upfront collaboration ensured successful and timely execution of the complex project.