Medupi Power Station

- Carbon Steel - Galvanized

The Medupi Power Station, located in Limpopo, South Africa, is one of the largest coal-fired power plants in the southern hemisphere. With an operational life of 50 years, the plant is comprised of size units operating at 800MW each.

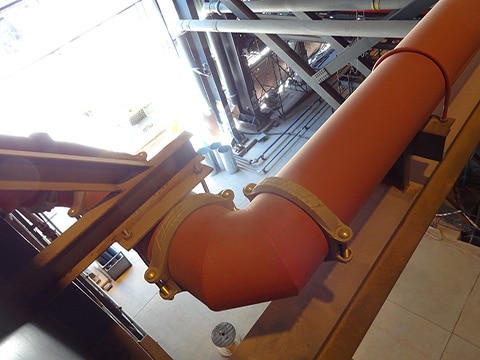

Victaulic’s grooved piping solutions provide installers with a fast and efficient installation method. Not only did the Victaulic solutions mitigate risk on the project, but also reduced the number of skilled construction laborers and improves jobsite safety. On this project, a wide range of Victaulic solutions was utilized on the fire protection and chilled water piping systems; this included grooved couplings, fittings, and valve portfolio for carbon steel pipe.

Victaulic joints are rolled grooved and eliminate the need for hot works, which reduces risk and improves safety. Additionally, the Victaulic flexible mechanically grooved products were chosen to reduce stress on the installed equipment, including pumps, chillers, and others.

The speed of installation resulted in a 60% labor savings on the installed fire protection system, while the HVAC system was installed 20% of the time that a welded system would have required.