Virginia Mall Tenant Improvement

- Carbon Steel

- Fire Suppression

- Improved Safety

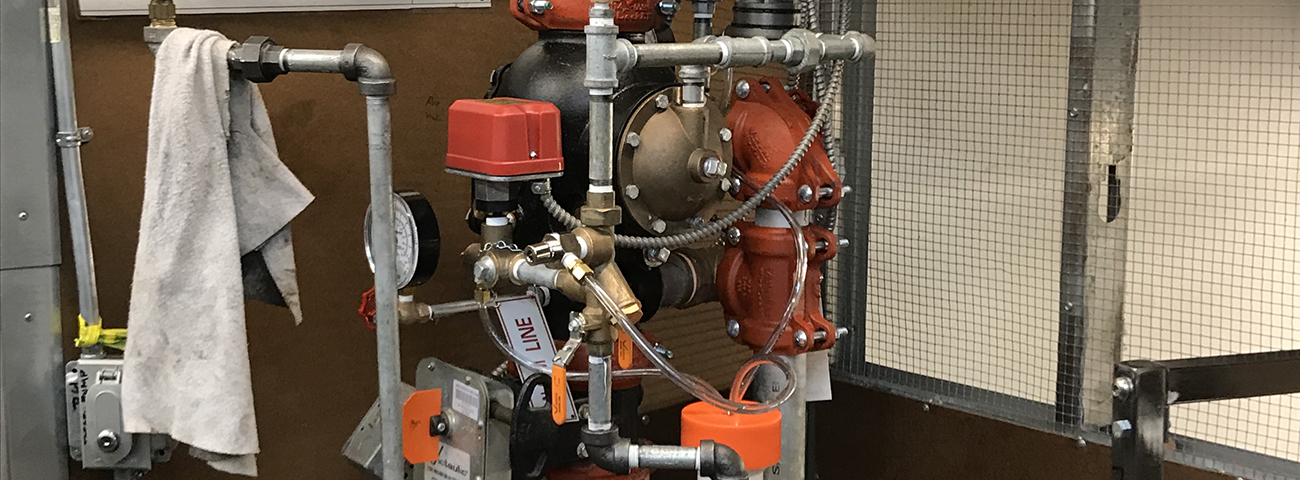

When a large mall in Chesapeake, Virginia, awarded Horizon Fire Protection Inc. a bid to retrofit the fire suppression system for a new tenant, the contractor seized the opportunity to showcase the value built into their work and impress owners with their novel methodology.

Victaulic’s Innovative Groove System (IGS™) RG2100 Roll Grooving Tool was used as a mess-free solution for grooving 1-inch hard pipe and VicFlex™ Series AH2-CC flexible sprinkler fittings with a captured-coupling were used to expedite connection to the branch line.

By using grooved solutions, Horizon Fire Protection Inc. was able to eliminate the need to thread. When the facilities manager witnessed how the IGS™ grooving tool and flexible fittings minimized metal shavings without using oils that would emit odors, he allowed Horizon Fire Protection Inc.’s crew to set up pipe preparation inside the workspace, rather than at a staging site in a far-off area of the mall.

“Not only did the system install four times faster than if it were threaded, by eliminating wrenches, we were able to minimize the wear and tear on our fitter’s shoulders and prevent injuries.” – Steve Kirby, Co-Owner and Vice President, Horizon Fire Protection.

Horizon Fire Protection Inc.’s success using Victaulic tools and solutions ultimately earned them a satisfied customer and additional projects at the mall. “This would have been a one and done job for us if it was not for the cleanliness and speed of Victaulic’s products, which played a huge role in impressing the customer.” Kirby adds.

External Links:

NFSA Retrofit Case Study, Victaulic