Posted on June 14, 2017

As Victaulic observes June as National Safety Month, we are reminded that achieving a level of world-class safety excellence is no accident. It is a journey. And with the safety journey, there is no ending point or destination. It is a constant drive for continuous improvement.

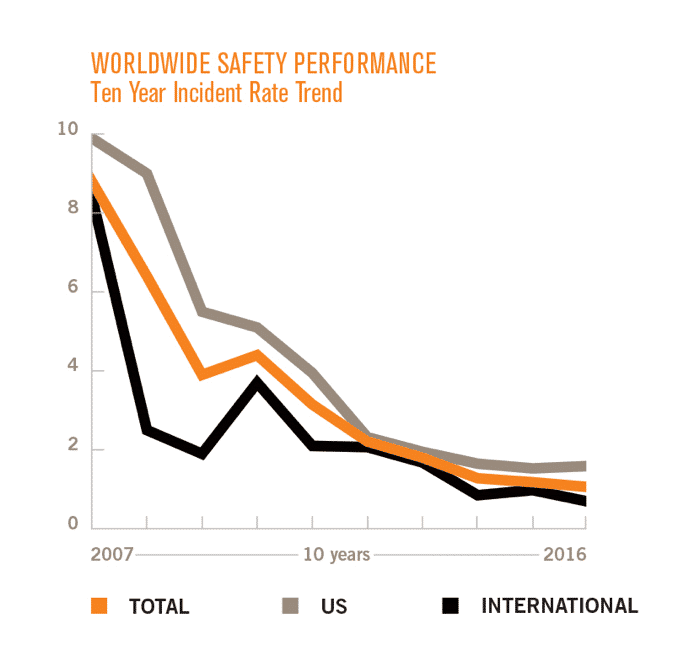

In 2016, Victaulic had its best safety year ever. Globally, we reduced our incident rate from 1.25 to 1.06, a  15% improvement from 2015. Since 2007, the company’s incident rate has decreased globally by 88%. This endeavor was a decade in the making and involved more than 40 company facilities around the world to see it through, as evidenced in the chart seen here.

15% improvement from 2015. Since 2007, the company’s incident rate has decreased globally by 88%. This endeavor was a decade in the making and involved more than 40 company facilities around the world to see it through, as evidenced in the chart seen here.

How does an organization go from a production-driven, minimal safety presence where injuries were expected as part of the work culture, to achieving world-class safety excellence? For many organizations, there is usually a crisis event or defining moment that alters a company’s perspective toward workplace safety and starts them on their journey. A new CEO or a significant internal or external safety event, perhaps. These types of events can galvanize an entire organization around a common course for improvement.

If your organization is looking to embark upon a path towards increased safety, here is Victaulic’s map to guide you.

Assess Your Strengths and Weaknesses

Before the journey can truly begin, an organization must assess current conditions (gap analysis). Conducting a gap analysis gives clear vision of an organization’s strengths and weaknesses.

Victaulic’s gap analysis revealed many strengths and several major safety building blocks in place to form the foundation of a great safety culture. These included:

- senior level executive support

- safety conscious plant managers and Director of Operations

- resource availability

- Facilities Excellence Mapping Program (FEM)

The Facilities Excellence Mapping Program was critical to jump-starting safety improvement because it mandated continuous improvement in the areas of safety, quality, production efficiency, Kanban and equipment. FEM’s formal structure and continuous improvement requirements through four phases of competencies placed ultimate responsibility for safety improvement squarely on the shoulders of each plant/facility manager. This program also facilitated a set of globalized safety standards to which all activities were being evaluated.

The analysis also revealed several improvement opportunities:

- The need for a corporate-level safety management representative

- The absence of a corporate-wide safety and health management system in place, which hindered global standardization

- Safety not perceived as a core competency or part of the company culture

Your organization’s strengths and weaknesses will vary, but it’s crucial to know where you stand internally, but also externally. Benchmarking in your industry takes place at this stage as well – what are other companies doing? How do you rate?

Establish and Communicate Your Vision

Once you can clearly see and understand the present state of your organization and in your industry, you can plot the path forward. With decision makers and managers who supported safety already in place, Victaulic had a vision early on – world-class safety.

Senior level executives helped define and communicate what the vision meant for the organization. Communicating a set of expectations and providing the necessary resources for developing a strategy fosters a strong safety culture. These expectations should be simple but profound:

- Improve employee awareness toward working and being safe, at home as well as at work.

- Enhance people’s behaviors and attitudes toward safety by creating clarity of purpose.

- Establish safety performance and continuous improvement requirements for each activity to pursue.

- Standardize safety worldwide so that all activities are guided by the same safety plans, programs and policies.

With a gap analysis complete and vision established, the safety journey can begin in true earnest.

Tune in later this month to read part two of our National Safety Month blog.