View this blog in another language:

Danish Finnish French German Norwegian Swedish

Posted on May 5th, 2024

In the lead-up to the recent United Nations COP28 climate summit in Dubai, the UN conducted the first-ever assessment of countries’ progress in meeting their commitments to cut greenhouse gas emissions under the 2015 Paris Agreement. Called the Global Stocktake, it looked at whether we’re on track in our efforts to limit global temperature rise to 2°C — and ideally to 1.5°C (2.7°F).

Short answer: Globally, we are not.

Even if we were on track, that would still leave plenty of progress to be made. To meet that 1.5°C goal, says the UN, emissions need to be cut by 43% from 2019 levels by 2030, and we need to reach net zero by 2050. It’s a daunting task. And the engineering and construction industry has a key role to play.

Embodied vs. operational carbon

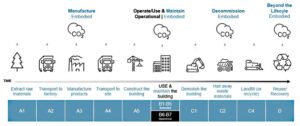

In 2021, the buildings and construction sector accounted for about 39% of energy- and process-related carbon dioxide emissions. Of those, 11% came from embodied carbon — the emissions associated with manufacturing building materials, transporting them to the site, constructing the building (Module A1 to A5) and, over time, maintaining (B1 to B5) and then demolishing it (C1 to C4).

And while that’s a far cry from the 28% associated with operational carbon — emissions that come from heating, lighting and other energy use that goes with occupying buildings (B6 to B7) — as buildings become increasingly energy-efficient and energy sources become lower-carbon, that 28% will decline. Can construction make the same kind of progress?

Whether it’s the appeal of cutting costs and waste, the urgency of rising temperatures and stakeholder pressure, or the lure of government incentives, firms are taking action. According to a Deloitte survey, 83% are promoting sustainable design, development, and construction practices, 76% are encouraging the sustainable use of resources and new materials, and 63% are reducing energy consumption.

It’s safe to say that all the above makes sustainability a buzz word within the global construction industry. But within that buzz, you can sense the uncertainty around how to achieve construction projects’ sustainability goals. There are many sustainability programs and incentives out there, and every country seems to be at a different stage. There are also various ways to measure your environmental impact, so which one should be used?

The truth is there is no easy answer. Just as construction is a puzzle, so is sustainability in construction. And this puzzle has more than one right way to successfully come together. There are many variables and dependencies unique to each project to consider, and only the overall project goals can point to the best path.

Like many of you, at Victaulic we are working to keep pace with the fast-moving global sustainability standards and do what it takes to fully serve our people and partners. One of the ways we are supporting our partners in achieving their sustainability goals is our ability to deliver on circularity.

Introducing circularity in construction

Circularity is one of the sustainability principles that has received a lot of attention, particularly in Europe. It is very similar to the cradle-to-cradle principle and takes the entire life cycle of a product into account. In simple terms, circular products are designed for long life, and can be recycled at their end-of-life or serve as raw material for another product and get a second life that way.

Adopting a circular mindset means making considerations and evaluating material selection taking the entire product and building life cycle into account- from production through use, maintenance, and end-of-life scenarios. This shift in mindset expands the evaluative criteria by which we may have traditionally thought about sustainable products and creates an opportunity to explore sustainable value creation across multiple dimensions. And when we look at products through these multiple dimensions, we get a more comprehensive look at their true potential for reducing environmental impact and waste. Or potentially, not.

For example, we see circularity happening in the cement industry in multiple ways. Waste is now used as a fuel in the high-temperature heating process for production of clinker (the primary ingredient in cement), replacing coal and petroleum coke. Mineral content of the waste is extracted for use as a clinker ingredient. By-products from other industries — fly ash from coal combustion, for instance — can also be a clinker component. And at end of life, concrete is 100% recyclable, either as aggregate in the production of a new generation of concrete or for road base and other applications.

At Victaulic, we are true believers in the Circular Economy Principles and we are proud champions of the only pipe joining method that fully delivers on circularity.

- Our production process is clean, modern and efficient using 100% recycled steel. And our products can be recycled back into their original state.

- Installations are clean and safe as well as flame and emissions free.

- Our solutions make piping systems infinitely reconfigurable, significantly reducing pipe waste. Pipe can be disassembled, cleaned and reused or repurposed at end of system life, reducing single-use materials.

- System maintenance is faster and easier, reducing risk and downtime.

If you are not taking circularity into consideration when evaluating your next construction project, you are likely missing an opportunity to reduce embodied carbon and make an impact on the achievement of your sustainability goals.

And it goes well beyond cutting embodied carbon. Employing a circularity mindset and incorporating components that support circularity can help you reduce your project’s impact on natural resources and society, cut waste, and ensure your project doesn’t place an undue burden on future generations. We’ll dive deeper into that part of the story as our series continues.

Part 2: Minimizing impact and waste prior to construction

Part 3: Reducing impact and waste on the site

Part 4: From an operational building to end-of-life scenarios

Our team is here to support your sustainability efforts. Not sure where to get started or what questions to ask? Connect with us and let’s partner together to build a sustainable future.