Posted on September 14, 2020

Industry experts, Kenneth Goodboy and Dr. Thomas Missimer, have recently published a paper titled “Evaluation of desalinated seawater vs. filtered raw seawater for heap leach copper extraction on mountaintop mines in arid regions” in the Desalination and Water Treatment Journal.

Kenneth Goodboy has an extensive background in water treatment systems, filtrations, and membranes. Goodboy earned a Chemical Engineering degree from Missouri University of Science and Technology. Currently, he is the President of Triple Point Separations Technologies, which is a Chemical Engineering consulting company, located in Wexford, Pennsylvania.

Dr. Thomas Missimer has made technical contributions in the fields of hydrogeology, groundwater hydrology, water management, geology, desalination, and water quality. Before becoming a professor at Florida Gulf Coast University, Dr. Missimer worked as a consultant for groundwater development, water management, and remediation of groundwater contamination for 35 years.

Many high-altitude mining projects require infrastructure for water supply for functions such as the on-site copper extraction. Engineers try to determine the least costly method to obtain process water, which is typically a choice between pumping treated seawater or desalinated seawater (freshwater) from the coast to the mine site, commonly 600–4,900 m above sea level and 10–200 km inland from the shoreline. Goodboy and Dr. Missimer conducted a detailed analysis of this problem to assess the key cost factors involved in water treatment, transport, and impacts on the heap leach process.

Grooved Solutions Save Valuable Time and Money

On the water supply pipelines for these high-altitude projects, having to perform in-the-field grinding of welds, non-destructive weld testing, coating the welds, and holiday testing the coating can severely increase and impact the construction schedule and project costs. In their analysis, Goodboy and Dr. Missimer identify how grooved products are considered a best practice for lined and coated pipelines. Specifically, they discuss how Victaulic’s grooved mechanical technologies provide for safer and more economical solutions for pipeline projects.

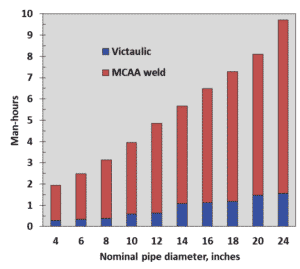

Victaulic’s solutions provide value engineering to a water pipeline project by significantly decreasing the direct installation man-hours. Goodboy and Missimer explain how Victaulic’s grooved pipe joining method directly impacts the labor required for pipeline projects.

Victaulic grooved mechanical couplings can decrease the field installation time vs. welds by a factor of 5.5 times on average for 102 to 610 mm (4 to 24 inches) diameter pipe as shown in the figure below. Grooved pipe joining can be utilized up to 2,743 mm (108 inches) diameter, and field installation labor savings grow exponentially as diameter increases.

Technologies for Pipeline are Needed and Utilized Globally

While Goodboy and Dr. Missimer’s paper primarily focuses on water pipelines for mining purposes, their findings expand to other applications and industries. Pipe joining capabilities are solutions that are required by many industries throughout the world. Commonly, the pipelines require corrosion and abrasion resistance/control.

Regardless of their purpose, these pipelines have similar specifications and requirements. The efficiencies of Victaulic’s mechanically grooved capabilities apply to pipelines utilized in numerous industries. As identified by Goodboy and Dr. Missimer, utilizing Victaulic’s grooved technology on lined and coated pipelines mitigates risk, creates certainty with schedule and budget, and provides inherent value engineering.

Victaulic’s innovative grooved solutions have provided safe and efficient ways to connect pipelines for over 100 years. The concept of joining pipelines with mechanical couplings established their viability after it successfully aided the Allied forces in the fuel and water pipeline distribution during World War II. Since then, many industries, such as oil and gas, mining, power, desalination, water and wastewater have had the confidence in Victaulic’s grooved technologies to provide solutions for their pipeline needs.

Learn More About Best Practices for Water Pipeline Projects

Goodboy and Dr. Missimer’s findings were recently accepted and published by the Desalination and Water Treatment Journal, which is dedicated to the “research and application of desalination technology, environment, and energy considerations, integrated water management, water reuse, and wastewater and related topics.”

Click here to read the full article and learn more about the most efficient way to manage lined and coated pipelines.

Also, click here to learn more about how Victaulic supports the infrastructure market.