Posted on September 23, 2019

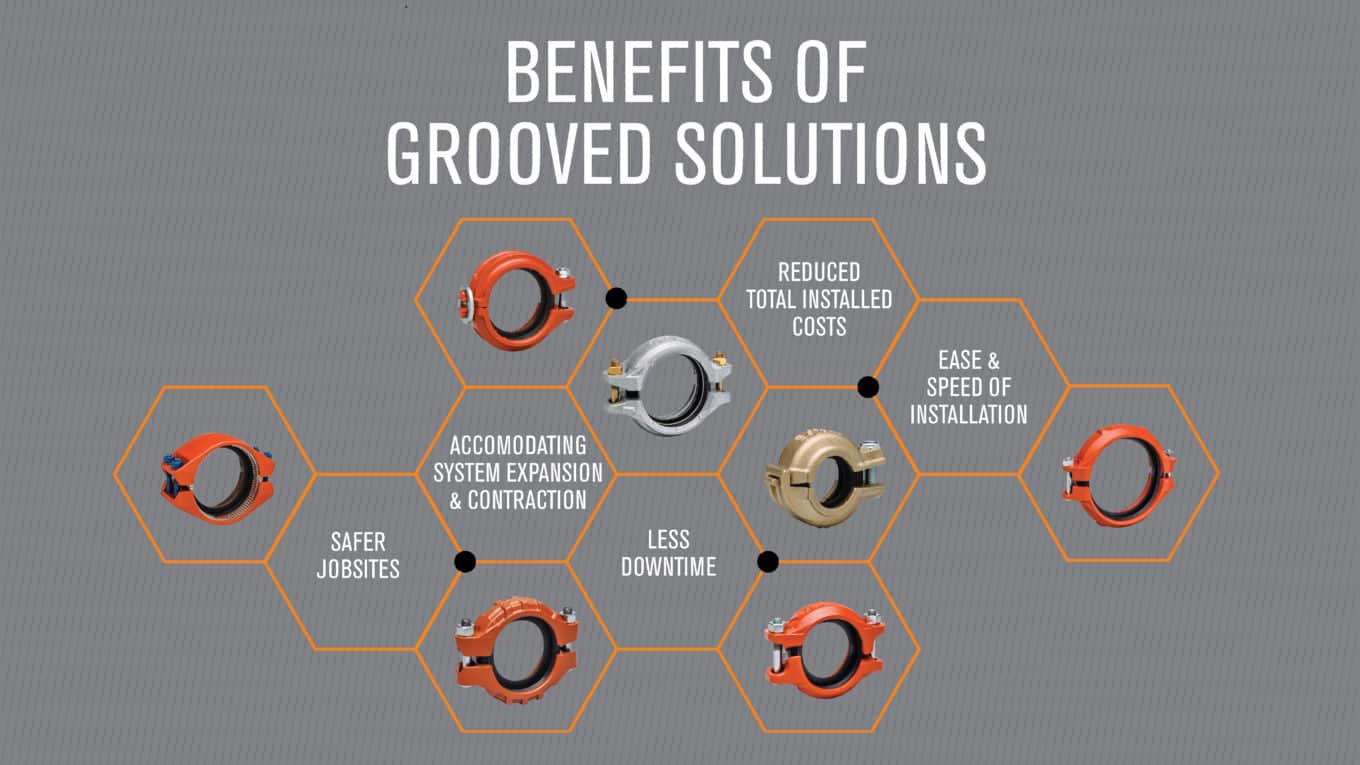

Grooved mechanical coupling systems are the most versatile, economical, and reliable grooved pipe joining system available today. Benefits of grooved pipe connectors to contractors include safer job sites, reduced total installed costs, and ease and speed of installation.

What is a Grooved Pipe Joint?

A grooved pipe joint consists of four elements

- the grooved pipe

- the gasket

- the coupling housings

- the nuts & bolts.

A pipe groove can either be cold formed or machine formed. A gasket encompassed by the coupling housing is wrapped around the two pipe ends, and the coupling housing key sections engage the grooves. The pipe coupling’s bolts and nuts are tightened with a socket wrench or impact wrench. In the installed state, the mechanical pipe coupling housing encases the gasket and engages the grooves around the circumference of the pipe to create a leak-tight seal in a self-restrained pipe joint.

Grooved pipe couplings can employ one of two basic styles: flexible or rigid. There are benefits to both styles. To read more on the differences between flexible and rigid grooved pipe couplings and when to use them, check out this blog post.

Top Five Benefits of Grooved Pipe Joints

1. Safer Jobsites

Not only do benefits of grooved pipe couplings include being fast and easy to install, but it’s also safer than any other pipe joining method. Grooved mechanical coupling systems are installed without the need for flame, eliminating the fire hazards typically associated with welding/brazing or soldering. Welding is one of the most dangerous industrial activities; its hazards include fire risk, electric shock, compressed gases, and toxic fumes. As such, welding requires personal protection for the eyes, hands, feet, and body. Welding activities also require a fire watch during and following the work, which can slow the construction schedule and increase costs.

The safety of installers on the job site is of the utmost importance; however, it becomes even more critical during expansion and/or retrofit projects where buildings such as hospitals and schools may remain open and operational during construction. The benefits of grooved mechanical couplings can decrease the risks to workers and in the projects mentioned above, building tenants. The grooved pipe joining method is the hands-down winner in a side-by-side safety comparison to welding, one of the most dangerous industrial activities.

2. Accommodating Piping System Expansion and Contraction

When accommodating thermal expansion and contraction in a piping system, the grooved pipe joining method conforms to industry practices. Simultaneously, it provides design flexibility, reduces stress on the mechanical piping system and provides a more compact, easy-to-inspect, and productive method of installation over other pipe joining methods.

Grooved mechanical couplings allow for movement of the pipe due to the design of their components. The dimensions of the pipe coupling housing key are narrower than the pipe groove allowing room for the pipe coupling housing key to move in the pipe groove. Additionally, the width of the pipe coupling housing allows for pipe end separation which in turn allows the grooved pipe joint to accommodate linear and angular movement. The mechanical coupling provides a self-restrained joint, and the unique pressure-responsive design of the pipe connector enables positive sealing even under deflection and linear pipe movement.

3. Less Downtime

In retrofit projects, avoiding disruption to building occupants while minimizing cost overruns associated with night and weekend work can be a challenge. Grooved mechanical pipe joining systems can address these issues as a reliable alternative to welding and flanging. The widely-accepted flame-free technology is fast and easy to install and maintain, providing compatibility between new system design and existing systems.

In many cases, existing piping systems can be rerouted and kept in operation while work is performed on old systems or while new systems are installed. The grooved system eliminates the need for complete system shutdowns because there is no need to drain and dry the system, and an arc or flame is not required to disassemble or reassemble the joint. As a result, buildings can return to full operating capacity very quickly. The benefits of grooved in this situation are simple: avoid downtime. To access a piping system joined with grooved components, a worker simply disassembles two couplings to drop out a pipe section. To complete the job, the grooved couplings are easily placed back on the pipe, and the nuts are tightened.

4. Reduced Total Installed Costs

Although there might be a higher upfront materials cost than with welding, the benefits of grooved are found in the reduction of labor time and labor costs. Based on the elimination of welding, and the need for highly skilled and relatively expensive labor, the assembly of mechanical coupling systems reduces labor man-hours as well as the labor rate. This contributes to an overall reduction in piping system costs, known as total installed costs. Victaulic estimates that jobs requiring welding applications demand up to 45 percent more man-hours on average over grooved piping solutions, and at a much higher labor rate.

5. Ease and Speed of Installation

Grooved mechanical piping is inherently faster to install than any other pipe joining method because the gasket and coupling housings simply need to be positioned onto the grooved pipe ends. The bolts and nuts are tightened with standard hand tools. Following installation, most grooved systems can be visually inspected. Metal-to-metal bolt pad contact confirms that the pipe coupling has been properly installed and secured into place. Welding, on the other hand, often requires X-ray inspections to ensure a sound joint. The benefits of grooved pipe couplings are demonstrated in the ease and speed of installation savings. Victaulic’s Installation-Ready™ mechanical pipe couplings can be installed up to ten times faster than welding and six times faster than flanging.

It’s easy to see the benefits of grooved piping systems and how it is quickly becoming the standard on commercial building job sites. With the ability to improve job site safety, speed and simplify installation, reduce total installed costs, and ease maintenance and expansion, grooved mechanical piping will long hold a place in contractors’ toolkits. When you add the engineering benefits to the mix—design versatility; accommodation of thermal expansion and contraction, deflection and seismic movement; and noise and vibration attenuation—grooved piping is in a class of its own.

Check out some of our case studies to see the benefits of grooved in action.