Posted on April 1, 2019

There are several reasons a historic or existing building may require a new heating or cooling system. For the first tip of our six-part series on mechanical retrofitting best practices, we discussed what is essential for effective project design and preparation.

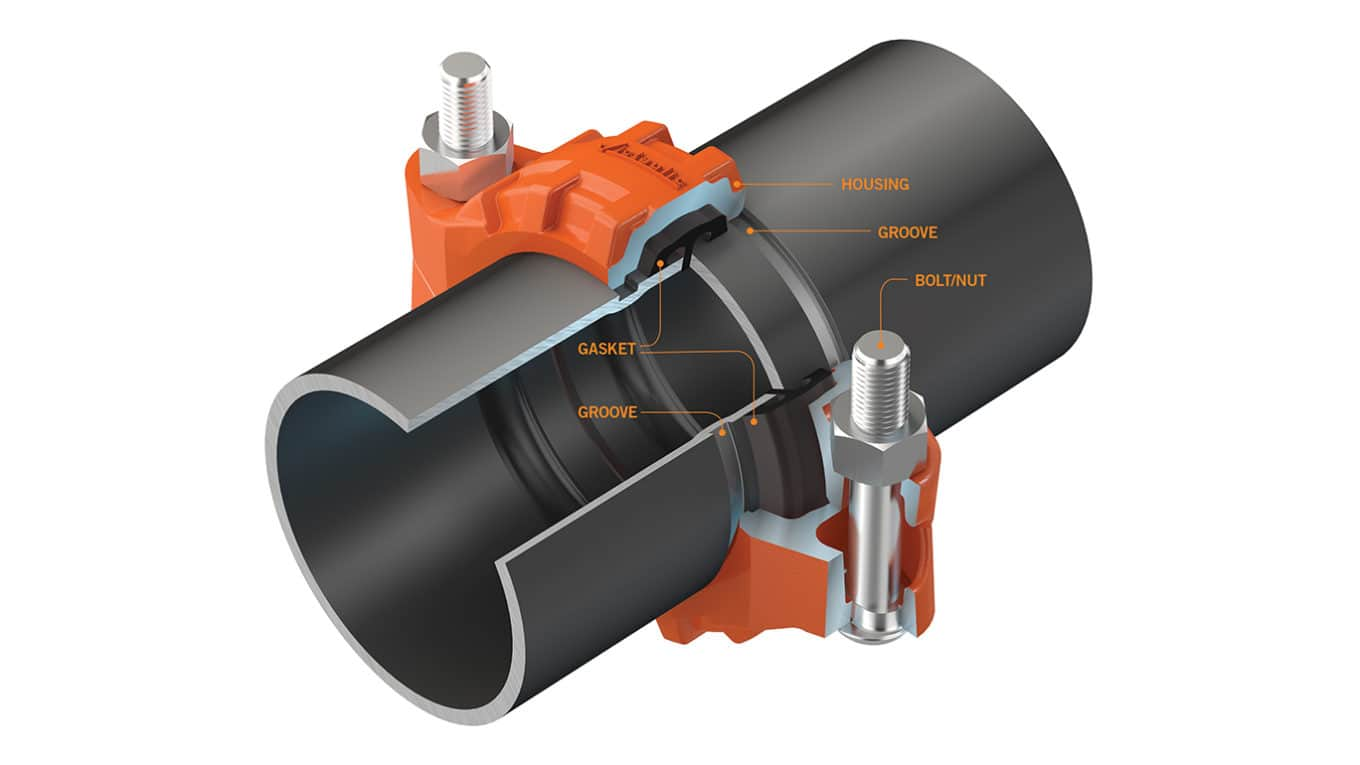

Tip Two: Select the Correct Mechanical Pipe Joining Method

Mechanical retrofitting best practices includes specifying a grooved design at the start of the project. A grooved mechanical pipe joining system is three to four times faster to install than a welded or flanged system. It doesn’t require jobsite preparation, unlike the extensive preparation necessary for welding.

Utilizing this flame-free pipe joining method removes the many health and safety concerns associated with welding. It eliminates the risk of fire during installation, damaging and discoloration of existing furniture and paint and the need for a hot work permit and safety watch. It also enhances safety and minimizes project risk due to the ease and speed of installation it provides, while reducing the total cost of installation.

Tune in for tip three on mechanical retrofitting best practices. It will explain how to prepare for unforeseen events and avoid major delays.

View the complete Mechanical Retrofitting Best Practices series here:

- Effective project design and preparation are essential

- Select the correct mechanical pipe joining method

- Take unforeseen circumstances and historic preservation & sustainability into account

- Maximize jobsite productivity

- Implement modular mechanical room to improve system efficiency

- Mechanical noise and vibration control methods