Installation-Ready™ Grooved Technology Pipe Couplings & Fittings

What Is Installation-Ready™ Technology?

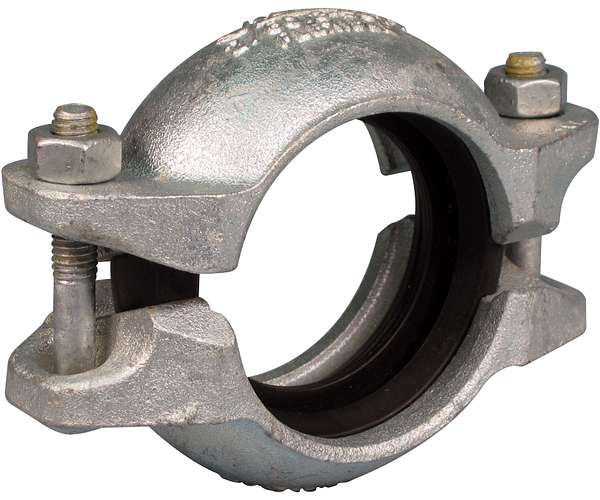

Victaulic’s patented Installation-Ready™ couplings provide fast, easy pipe connections, and reduce the number of loose parts to drop or misplace. The single-unit design allows an installer to assemble the coupling or fitting simply by inserting it onto the grooved end of a pipe and tightening the nuts.

Why is it different?

Prior to this technology, in order to install a grooved coupling, the coupling itself was completely disassembled and then reassembled onto the pipe ends.

The process looked like this:

- Remove the bolts and nuts

- Remove the gasket

- Fit the gasket over the gap between two grooved pipe ends

- Wrap the housings around the gasket

- Tighten the bolts and nuts

This 5 step process which took only minutes to accomplish was a complete game changer when it was introduced in 1919 as an efficient alternative to welding. Nearly a century later, Victaulic is developing new ways to build on that original innovation. When our customers asked us how we could make grooved couplings even faster, safer and more durable, we responded with patented Installation-Ready™ Technology.

Grooved couplings, and the more recently released grooved fittings featuring Installation-Ready™ technology come pre-assembled; they are simply pushed on to a grooved pipe end, joined by a second grooved pipe end, and then bolts and nuts are tightened. What used to take minutes — now takes only seconds.

How Much Faster Is Installation-Ready™ Technology Vs. Other Joining Methods?

- Install up to 10 times faster than welded joints

- Install up to 6 times faster than flanged joints

- Install in less than half the time of standard grooved couplings

What Are the Benefits of Installation-Ready™ Technology?

- COMPRESSED PROJECT SCHEDULES - Due to the speed at which these couplings can be installed, as outlined above, contactors are able to further compress their construction schedules.

- REDUCE MATERIAL HANDLING - Unlike standard couplings, Installation-Ready™ couplings are installed without the need to disassemble the coupling. No loose bolts and nuts translates to less material handling on site.

- BETTER MANAGED LABOR RISK- Because Installation-Ready™ couplings require fewer steps to install, the result is consistently faster pipe joints; this allows contractors to optimize crew size and better manage their labor risk.

- ENHANCED JOB SITE SAFETY - No flames. No fumes. No loose parts. In addition to being flame-free and devoid of noxious fumes during installation, Installation-Ready™ couplings feature no loose parts to drop or lose, reducing material handling on site, thereby reducing risk of injury.

Installation-Ready™ Technology Video Library

INSTALLATION-READY™ TECHNOLOGY RESOURCES

- All Products

- Pipe Joining

- Fittings

- Flow Control

- Tools

|

FireLock™ Installation-Ready™ Style 009V Rigid Coupling

|

|

|

|

QuickVic™ Style 107V Rigid Coupling

|

|

|

Style V9 FireLock™ IGS™ Installation-Ready™ Sprinkler Coupling

|

|

|

FireLock EZ™ Style 009N Rigid Coupling

|

|

|

Series 906 Knife Gate Valve for HDPE Pipe

|

|

|

Installation-Ready™ Style 644 Transition Coupling

|

|

|

Installation-Ready™ Style 357 Rigid Coupling For CPVC/PVC Pipe

|

|

|

Installation-Ready™ Style 356 Transition Coupling For CPVC/PVC Pipe

|

|

|

Style 904 Flange Adapter for HDPE-to-Flanged Pipe

|

|

|

Style 905 Coupling for HDPE

|

|

|

Style 907/W907 HDPE-to-Steel Transition Coupling

|

|

|

Series 795 Knife Gate Valve

|

|

|

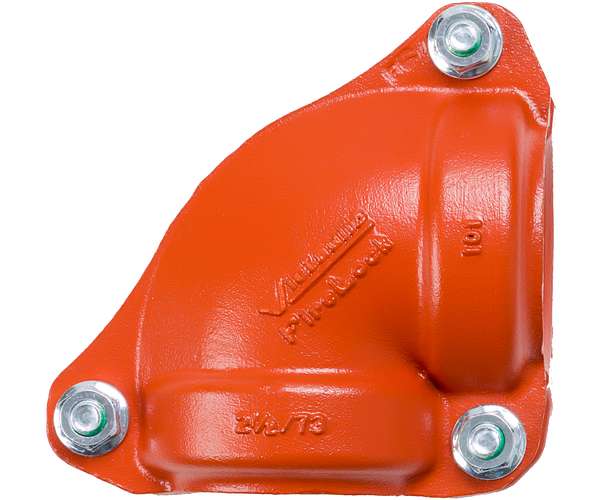

FireLock™ Installation-Ready™ Grooved Fittings

|

|

|

FireLock™ IGS™ Installation-Ready™ Fittings

|

|

|

Installation-Ready™ Style SC77 Flexible Coupling for Shouldered Steel Pipe

|

|

|

QuickVic™ Style 177N Flexible Coupling

|

|

|

Installation-Ready™ Style 171 Flexible Composite Coupling

|

|

|

Style 607 QuickVic™ Installation-Ready™ Rigid Coupling for Copper Tubing

|

|

|

QuickVic™ Style 107N Rigid Coupling

|

|

|

FireLock™ IGS™ Installation-Ready™ Style 108 Rigid Coupling

|

|

|

FireLock™ Installation-Ready™ Style 109 One-Bolt Rigid Coupling

|

|

|

QuickVic™ Installation-Ready™ Style 807N Rigid Coupling for Potable Water Applications

|

|

|

QuickVic™ Installation-Ready™ Style 877N Flexible Coupling for Potable Water Applications

|

|

|

|

Installation-Ready™ Series 122 Rubber-Lined Butterfly Valve with Aluminum Bronze Disc

|

|

|

|

Installation-Ready™ Series 124 Rubber-Lined Butterfly Valve with Stainless Steel Disc

|

|

|

Style HP-170 Rigid Coupling

|

|

|

PS3400 Adjustable Pipe Stand

|

|

|

RG2300 Combo Roll Grooving Tool

|

INSTALLATION-READY™ TECHNOLOGY DOWNLOADS

- All Resources

- Submittals

- Manuals

- Technical & Design Data

- Certifications & Approvals

| Resource | Number | Downloads | Collection |

|---|---|---|---|

| QuickVic™ Style 107V Rigid Coupling Submittal | 06.33 |

|

|

| QuickVic™ Style 107V Rigid Coupling Installation Instructions | I-107V |

|

|

| FireLock™ IGS™ Installation-Ready™ Style V9 Sprinkler Coupling Installation Instructions (I-V9) | I-V9 |

|

|

| FireLock™ Style 009V, Style 009N and Style 109 Installation-Ready™ Rigid Couplings Submittal | 10.64 |

|

|

| FireLock™ IGS™ Installation-Ready™ Style V9 Sprinkler Coupling Submittal | 10.65 |

|

|

| Installation-Ready™ Series 795 and 906 Knife Gate Valves Installation Instructions | I-795-906 |

|

|

| Series 906 Knife Gate Valve for HDPE Pipe Submittal | 19.06 |

|

|

| Installation-Ready™ Series 795 and 906 Knife Gate Valves Maintenance Quick Guide | I-795-906-MNT |

|

|

| Installation-Ready™ Style 644 Transition Coupling Installation Instructions | I-644 |

|

|

| Installation-Ready™ Style 644 Transition Coupling Submittal | 22.44 |

|

|

| Installation-Ready™ Style 356 Transition Coupling Installation Instructions | I-356 |

|

|

| Installation-Ready™ Style 357 Rigid Coupling Installation Instructions | I-357 |

|

|

| Installation-Ready™ Style 356 Transition Coupling Submittal | 33.06 |

|

|

| Installation-Ready™ Style 357 Rigid Coupling Submittal | 33.07 |

|

|

| Style 904 Flange Adapter for HDPE-to-Flanged Pipe Installation Instructions | IT-904 |

|

|

| Style 904 Flange Adapter for HDPE-to-Flanged Pipe Submittal | 19.12 |

|

|

| DNV Type Approval - Grooved End Fittings |

|

||

| IGS™ Groove Specifications | 25.14 |

|

|

| Style 905 Plain End Coupling for HDPE Installation Instructions - Metric Sizes | I-905-Metric |

|

|

| Style 905 Plain End Coupling for HDPE Installation Instructions | IT-905 |

|

|

| Style 907 Transition Coupling for HDPE Installation Instructions | IT-907 |

|

|

| Installation-Ready™ Flexible Coupling Style SC77 Installation Instructions | I-SC77 |

|

|

| Style 907 Transition Coupling for HDPE Installation Instructions - Metric Sizes | I-907-Metric |

|

|

| Installation-Ready™ Series 795 Knife Gate Valve Installation Instructions | I-795 |

|

|

| Style 171 Installation-Ready™ Composite Flexible Coupling Installation Instructions | I-171 |

|

|

| FireLock™ Installation-Ready™ Fittings Installation Instructions (I-102-104) | I-102-104 |

|

|

| FireLock™ Installation-Ready™ Fittings Installation Instructions (I-101/103) | I-101_103 |

|

|

| QuickVic™ Installation-Ready™ Style 607 Rigid Coupling for Copper Tubing Submittal | 22.13 |

|

|

| Installation-Ready™ Fittings for Grooved Copper Tubing Submittal - Discontinued Product Support | 22.15 |

|

|

| Plain End HDPE Fittings Submittal | 19.11 |

|

|

| Style 907 Transition Coupling for HDPE Submittal | 19.10 |

|

|

| Style 905 Plain End Coupling for HDPE Submittal | 19.07 |

|

|

| Installation-Ready™ Style SC77 Flexible Coupling for Shouldered Pipe Submittal | 16.10 |

|

|

| FireLock™ Installation-Ready™ Style 109 One-Bolt Rigid Coupling Installation Instructions | I-109 |

|

|

| QuickVic™ Installation-Ready™ Style 807N Rigid Coupling for Potable Water Installation Instructions | I-807N |

|

|

| QuickVic™ Installation-Ready™ Style 877N Flexible Coupling for Potable Water Installation Instructions | I-877N |

|

|

| Style HP-170 Rigid Coupling Installation Instructions | I-HP170 |

|

|

| QuickVic™ Installation-Ready™ Style 807N Rigid Coupling for Potable Water Applications Submittal | 06.28 |

|

|

| QuickVic™ Installation-Ready™ Style 877N Flexible Coupling for Potable Water Applications Submittal | 06.29 |

|

|

| Installation-Ready™ Series 122 Rubber-Lined Butterfly Valve with Aluminum Bronze Disc Submittal | 08.32 |

|

|

| Installation-Ready™ Series 124 Rubber-Lined Butterfly Valve Submittal | 17.44 |

|

|

| Style HP-170 Rigid Coupling Submittal | 06.18 |

|