Posted on September 3rd, 2025

Consultoría y Diseño en Climatización is an engineering firm located in Colombia, owned and operated by professional engineer and master in sustainable architecture, Ernesto Porras.

He believes that air conditioning projects must be designed from the beginning to be environmentally friendly, operate at maximum energy efficiency, offer good indoor air quality, and provide adequate thermal comfort for its occupants.

He cares about providing personalized attention and solutions that satisfy the needs of his clients through innovative and reliable engineering methodologies that allow his team to be at the forefront of issues such as sustainability, energy efficiency, health, well-being, and people productivity.

Utilizing Value-Added Solutions to Improve Efficiency

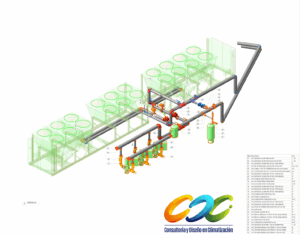

The team at Consultoría y Diseño en Climatización was tasked with designing the 440 TR asymmetrical chilled water plant with ultra-efficient chillers using 1234ze refrigerant at a university in Cali, Colombia. Due to their long history working with the Victaulic sales team in Colombia and the mutual trust and respect developed over the years, the engineering team chose to work with Victaulic to implement value-added solutions to improve the efficiency of the design of the piping system. By utilizing Victaulic Tools for Revit for the modeling of the piping systems, improving the efficiency of the modeling design improved, as did the accuracy of the procurement, overall increasing the efficiency of installation of the project.

The chilled water system consists of 1 ½” to 8” standard wall carbon steel pipe. Victaulic QuickVic SD Installation-Ready Couplings, fittings and valves were used for installation of the 1 ½” piping. For the 2” to 8” piping

, Style 107V QuickVic™ Rigid couplings, Style 177N QuickVic Flexible couplings, Style 741 Flange Adapters, Series 761 Vic-300TM MasterSealTM Butterfly Valves, Series 380 Discharge Vibration Isolation Pump Drops, Series 381 Suction Vibration Isolation Pump Drops, Style 923 Strapless Outlet, Style 924 Victaulic Strapless Thermometer Outlet and Victaulic OGS grooved fittings were utilized.

Victaulic prefabricated and QuickVic™ products offered multiple benefits on this project: they attenuate noise and vibration, eliminating the need for anti-vibration seals. The Victaulic prefabricated vibration isolation pump drops, reduce the number of field joints, improving installation efficiency and reducing risk. The pump drops are more compact than flanged installation and are more cost-effective to install. During system downtime, due to maintenance, the use of Victaulic groove products will allow the on-site maintenance teams to perform their duties more

Victaulic prefabricated and QuickVic™ products offered multiple benefits on this project: they attenuate noise and vibration, eliminating the need for anti-vibration seals. The Victaulic prefabricated vibration isolation pump drops, reduce the number of field joints, improving installation efficiency and reducing risk. The pump drops are more compact than flanged installation and are more cost-effective to install. During system downtime, due to maintenance, the use of Victaulic groove products will allow the on-site maintenance teams to perform their duties more

efficiently when compared to working with flanged components

Another reason why Mr. Porras chose to work with Victaulic is that we have a joint commitment, to offering sustainable solutions for our clients and thereby improving the quality of life in buildings. Victaulic manufactures products with up to 98% recycled content, using the most advanced and clean technology. In addition, our products are fully recyclable once they are decommissioned, allowing them to be returned to their original state and promoting a sustainable life cycle.