Downstream Air Compression Facility for Sullair

- Fabrication

- Virtual Design & Construction

- Stainless Steel

- Compressed Construction Schedule

- Ease of Installation

- Simplified System Maintenance

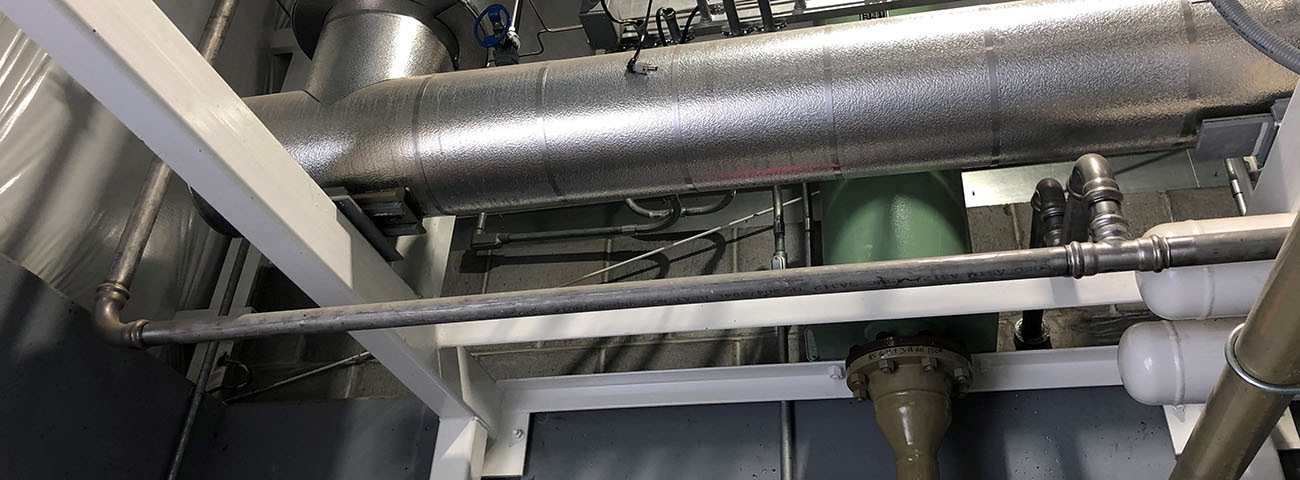

Critical piping systems, including air and water supply, are essential to bring a facility online and begin operating. Once online, these critical applications must operate consistently and reliably to mitigate facility downtime and delays in production.

Victaulic system solutions were recently installed on a critical piping system at an air compressor facility in Midland, Michigan. With a goal of mitigating the risk of cost overages and installation delays, the owner chose to utilize Victaulic stainless steel system solutions on the compressed air system. Victaulic VicPress™ was selected for the ¾ – 1 ½’’ piping, with stainless steel couplings and fittings specified for the 2 – 4’’ system.

Material arrived onsite according to the owner’s build strategy and Victaulic field engineers partnered with the customer throughout the installation. The Victaulic system was installed with ease, and the visual verification of proper installation provided the owner with confidence that the compressed air supply lines would operate reliably for the life of the facility.

Now operational, the air compressor facility will continue to experience the benefits of Victaulic system solutions throughout ongoing maintenance. By providing a union at every joint, Victaulic’s value engineered mechanical joining system is easy to disassemble, providing quick access to the system to minimize downtime and reduce scheduled maintenance.

By selecting Victaulic this facility owner was able to mitigate risk and maximize productivity, all while reducing total installed cost.