Governor Mario M. Cuomo Bridge

- Carbon Steel - Galvanized

- Accommodate for Angular Deflection

- Accommodate for Building Sway

- Accommodate for Thermal Movement

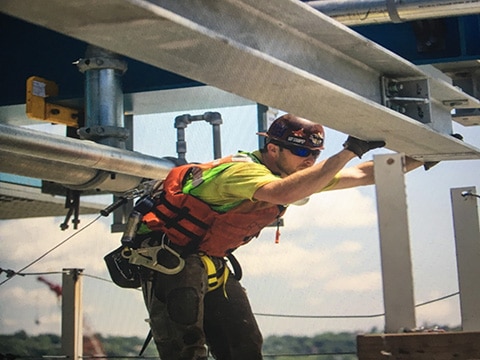

The new Governor Mario M. Cuomo Bridge recently replaced the Tappan Zee Bridge in New York with state-of-the-art twin spans over the Hudson River, connecting Rockland and Westchester counties. The $3.98 billion 3.1-mile Cuomo Bridge is one of the largest design-build transportation projects in the United States. It’s also a vital route for residents, commuters, travelers, and commercial vehicles.

When the New York State Thruway Authority moved to replace the old Tappan Zee Bridge, it was carrying more than 140,000 vehicles per day – far more than it was intended to handle. The new Cuomo Bridge was designed to support mass transit and a future commuter rail for 100 years.

The mega infrastructure project was designed and built by a consortium of engineering and construction firms, including U.S. companies Fluor Corporation and subcontractor Jett Industries. Victaulic bridge drainage and fire suppression standpipe systems were chosen due to the contractors’ confidence in the long-term service life and product qualifications. On the bridge, the following Victaulic solutions were utilized on the galvanized carbon steel roll grooved pipe:

- Style 72 Outlet Couplings

- Style 77 Flexible Couplings

- Style 107 QuickVic Rigid Couplings

- Style 177 QuickVic Flexible Couplings

- Style 741 Flange Adaptors

The Victaulic solutions utilized on the Cuomo Bridge have the ability to accommodate movement on a bridge that experiences expansion, contraction, deflection, and sway. The use of Victaulic products helped solidify trust that the Cuomo Bridge will indeed last a century.

External Links