Sheridan College

- Fabrication

- Project Modeling

- Virtual Design & Construction

- Carbon Steel

- Compressed Construction Schedule

- Confined Space Installation

- Cost and Schedule Certainty

- Design Flexibility

- Ease of Installation

- Engineered Product Solutions

In 2016, Sheridan College invested $47.5 million at its David Campus in Brampton, Ontario, to construct a new, state-of-the-art learning facility with 22 flexible classrooms, a learning commons and dedicated workshops for skilled trade programs. Additionally, the facility’s district energy center was built and designed to allow students to view the campus’ seven hydronic systems up close.

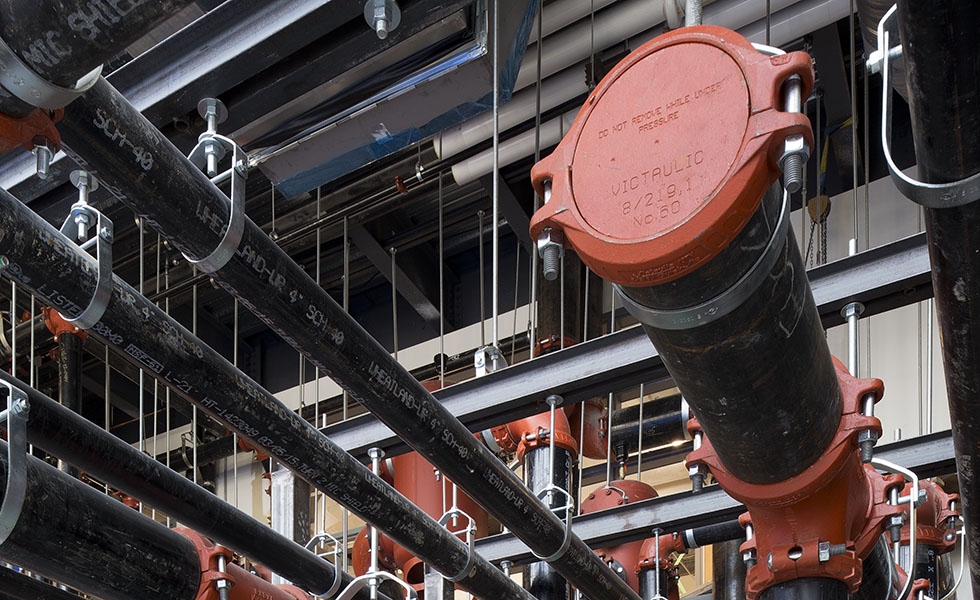

With Canada’s frigid winter months quickly approaching, Insight Engineering and Construction, the project contractor, partnered with Victaulic to compress the design and installation timeline for four heating systems in the three-story, 130,000-square-foot building. Since the district energy center needed to be built within a reduced footprint that left room for the glass enclosure and student viewing areas, Victaulic’s Virtual Design and Construction (VDC) team was also engaged to provide confined space installation solutions.

The Victaulic VDC team leveraged 3D modeling when collaborating with Insight to optimize equipment and piping layout. The models enabled the contractor and mechanical engineer, The Aquila Group, to identify and address potential issues before materials arrived at the campus. To further accelerate the schedule, the teams created a unique sequence to install priority piping systems efficiently and set up fabrication shops onsite to minimize lead time between receiving drawings and installing spools. Victaulic’s Installation-Ready™ couplings, valves, fittings, and pre-assembled Koil-Kits™ Coil Packages were used on the chilled beams and terminal coil hookups.

Victaulic’s VDC team and grooved solutions helped Insight fabricate, install, and start up the district energy center’s heating system ahead of schedule — right in time for the new semester.

External Links

College’s Hydronic Installation Meets Fast-Tracked Deadline ES Engineered Systems