Snoqualmie Falls Power Plant

- Carbon Steel

- Stainless Steel

The Snoqualmie Falls hydroelectric power plant, built in 1898, has been operational for more than 115 years and is one of the oldest power plants in the United States. The station has two powerhouses that have a combined generating capacity of 54 MW. The original powerhouse became the world’s first underground power plant. The second was constructed a decade later and resides a short distance from the falls.

In 2010, PSE’s Snoqualmie Falls Power Plant began a four-year refurbishment project, including updates to the plant infrastructure and recreational areas, which concluded in March 2014. PSE utilized easy-to-install Victaulic products on the plant’s penstock, cooling water, sump pump, lube oil, and compressed air lines.

Most of the piping for the project was prefabricated in southern California and transported to the site, including 85 – 121″/ 2160 – 3070mm Style 231 Non-Restrained Flexible Expansion Couplings, which provided the flexibility and expansion capabilities needed for this type of large diameter piping.

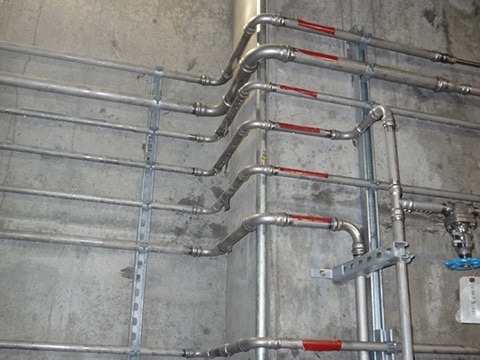

Additionally, Style 89 Rigid Couplings and Series 761 Vic-300™ Masterseal™ Butterfly Valves were utilized throughout the stainless steel cooling water, sump water, and drain piping systems located inside the powerhouse. The lube oil and compressed air piping systems utilized the Victaulic Vic-Press™ solutions.