Southern Sea Water Authority Perth 2 Desalination Plant

- Stainless Steel

- Compressed Construction Schedule

- Cost and Schedule Certainty

- Ease of Installation

The Southern Seawater Authority Perth 2 Desalination Plant was designed to support the greater Perth Region of Western Australia. The plant was constructed to support the increase in water consumption that was created through population growth and reduced rainfall.

The Southern Sea Water Authority needed to find a solution that would reduce the project schedule on the facility that was being built to support the mandate to produce water for Western Australia. Victaulic’s grooved piping products and solutions were able to reduce the project schedule, labor, and costs on the facility.

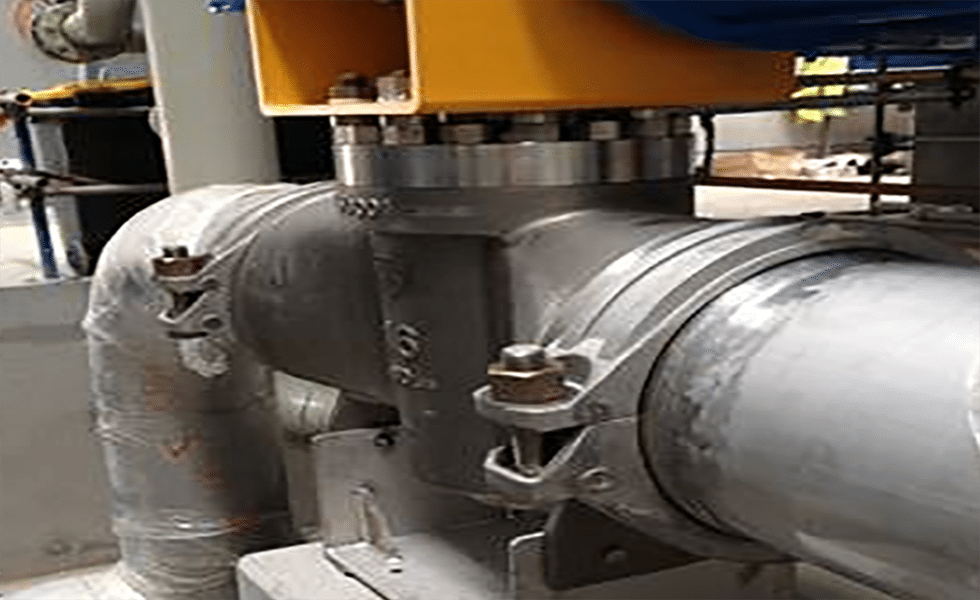

Victaulic’s Virtual Design and Construction Team presented to SSWA conversions of welded joints, flanged joints, and valve assemblies to Victaulic grooved piping solutions. The solutions included the StrengThin™ System for high pressure on thin-wall super duplex stainless steel piping. The Victaulic solutions were utilized on the high-pressure reverse osmosis system.

The rapid field assembly of the StrengThin system and Victaulic high-pressure plug valves dramatically reduced field man-hours and assisted in creating schedule certainty. The total field installation time for a complete 16″ | DN400 valve assembly was reduced from 2½ days to 10 minutes.

The Southern Sea Water Authority Perth 2 Desalination Plant has the potential to deliver 30% of the state’s water supply from climate independent water sources.