Posted on March 22, 2021

Victaulic has a rich history of optimizing mine backfill, dating back to the inception of paste reticulation systems over 2 decades ago. Our unwavering commitment to continuous innovation and value engineered solutions has allowed us to develop industry-leading diverter valves, that are being used in mines around the world.

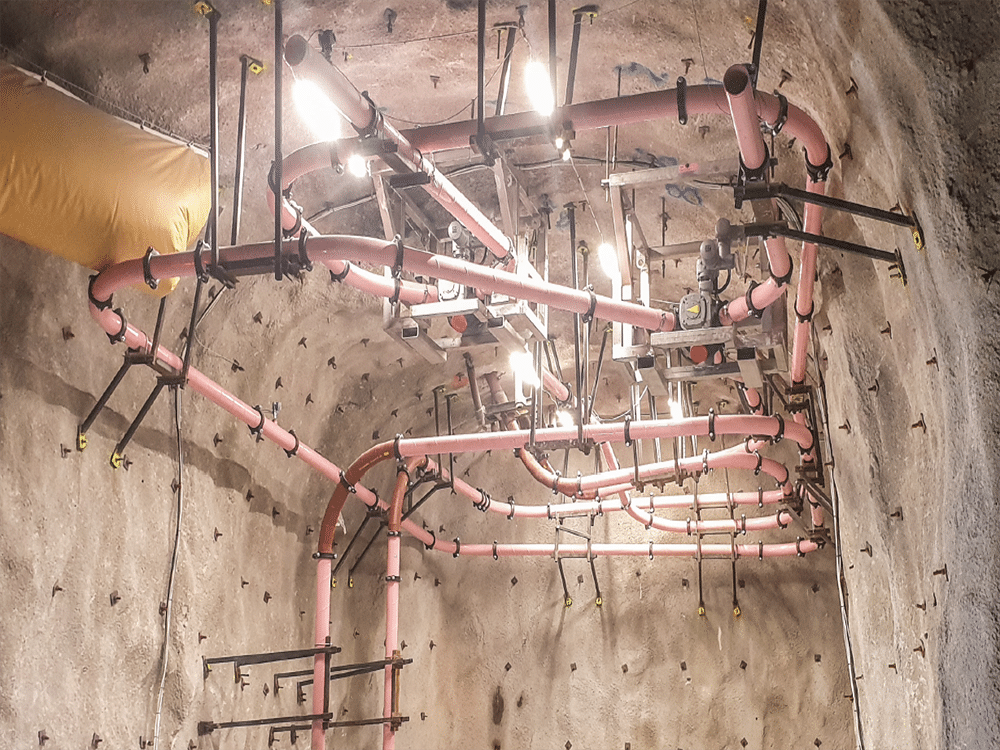

Here is a look inside some of these global mines with a spotlight on Victaulic diverter valves in situ. These valves are used for diversion, flushing, and emergency dumping, mitigating the risk of system damage while optimizing mine backfill.

Click here to explore Victaulic’s innovative system solutions for paste reticulation.