Tool Rental

We understand your tool needs vary by project. Renting provides you the flexibility to secure the right equipment for the job while reducing costs. Our rental fleet lends solutions for pipe end preparation from roll grooving tools to hole cut tools. Contact us today for tool availability.

-

Financing

Victaulic is committed to accommodating your needs through support, service and high quality products. Helping you meet your deadlines is important to us. When it comes to financing large investments you should be able to choose the option that makes sense; whether that be buying, renting or leasing. Let us help you meet your project demands.

Support & Service

At Victaulic, we provide state-of-the-art tool technology integrated with unparalleled service and support.

Our Tool Tech team works closely with our customers ensuring we are conscious of the challenges they may face on a day to day basis and work with them toward the appropriate solution.

Product Lifecycle Support

We warrant all products be free from defects in materials and workmanship under normal conditions of use and service. Our obligation under this warranty is limited to repairing or replacing at our option at our factory any product which shall within one year after delivery to original buyer be returned with transportation charges prepaid, and which our examination shall show to our satisfaction to have been defective.

Features & benefits

PIPE END PREPARATION TOOL PRODUCTS

- All Products

- Tools

|

PC3110 Cut & Mark Tool

|

|

|

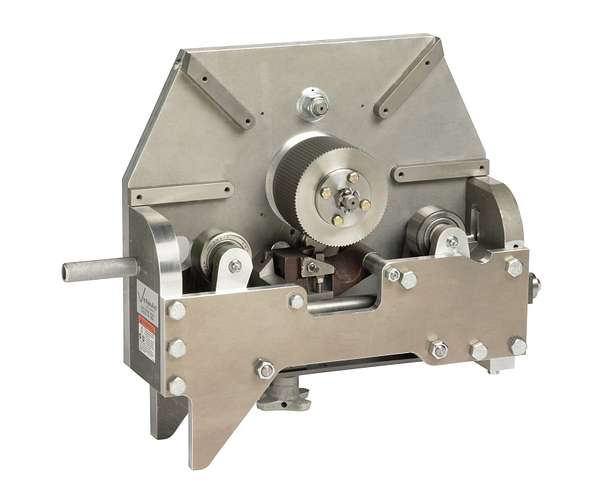

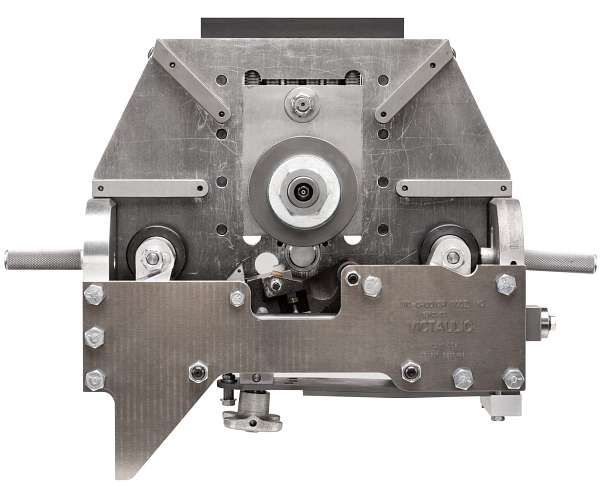

RG3210 Roll Grooving Tool

|

|

|

RG3600 StrengThin™ 100 Roll Grooving Tool

|

|

|

VG824 Cut Grooving Tools

|

|

|

VG828 Cut Grooving Tool

|

|

|

VHCT900 Hole Cutting Tool

|

|

|

Vic™-Tap II Hole Cutting Tool

|

|

|

VE26 Roll Grooving Tool

|

|

|

VE206 Portable Roll Grooving Tool

|

|

|

VE226 Roll Grooving Tool

|

|

|

VE268 Roll Grooving Tool

|

|

|

VE270FSD/271FSD Roll Grooving Tool

|

|

|

VE272SFS Roll Grooving Tool

|

|

|

VE460 Roll Grooving Tool

|

|

|

VE46 Roll Grooving Tool

|

|

|

VG26/VG28 Cut Grooving Tool

|

|

|

VE414MC Roll Grooving Tool

|

|

|

VE416FSD/VE417FSD Roll Grooving Tool

|

|

|

VE416FS Roll Grooving Tool

|

|

|

VE106/VE107 Roll Grooving Tool

|

|

|

RG1200 OGS-200 Roll Grooving Tool

|

|

|

CG1100 Cut Grooving Tool

|

|

|

VG Cut Grooving Tool

|

|

|

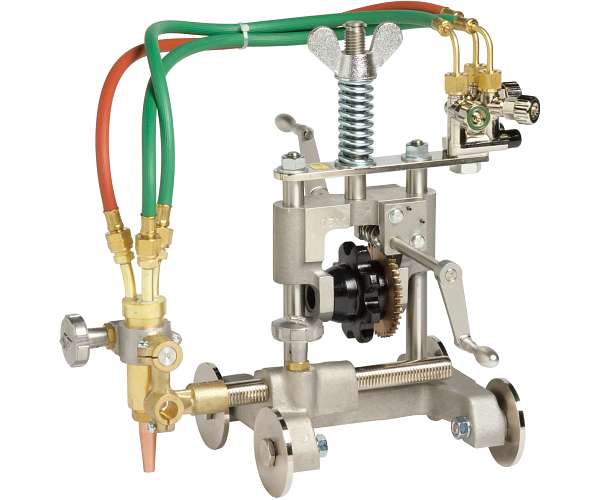

VG412 Orbital Cut Grooving Tool

|

|

|

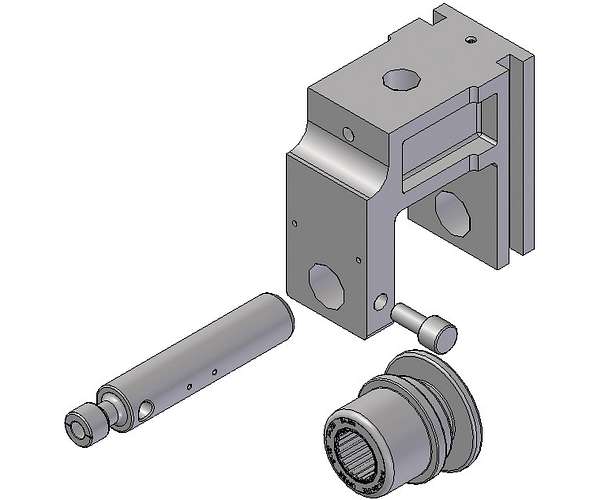

VE436MC Tool Conversion Kit

|

|

|

VE450FSD Roll Grooving Tool

|

|

|

VE12/VE12SS Roll Grooving Tool

|

|

|

VCT2 Automatic Pipe Cut-Off Tool

|

|

|

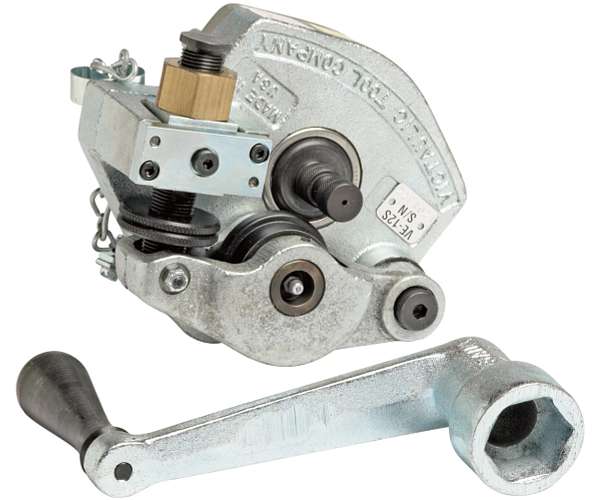

VCT1 Manual Pipe Cut-Off Tool

|

|

|

Vic-Press™ PFT510 Tool

|

|

|

HCT908 Hole Cutting Tool

|

|

|

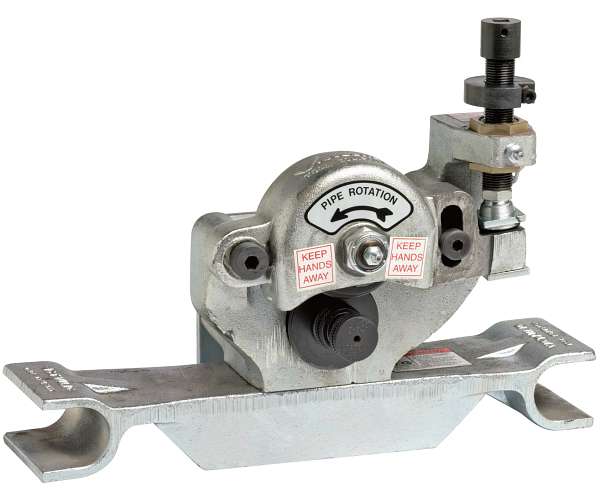

CTM-02 Large Manual Tool

|

|

|

CTM-01 Small Manual Tool

|

|

|

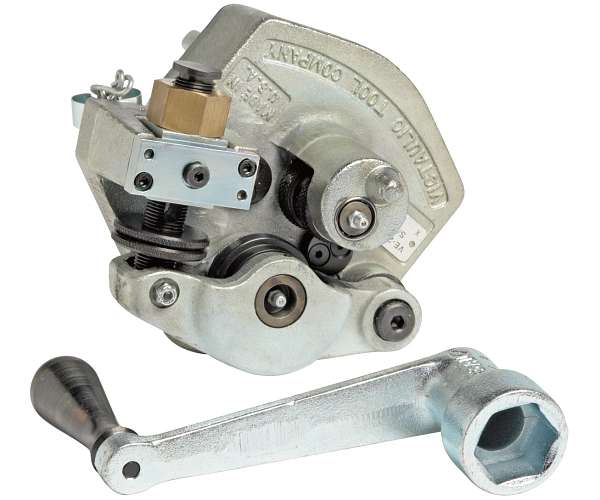

CTH-02 Large 25-Ton Hydraulic Tool

|

|

|

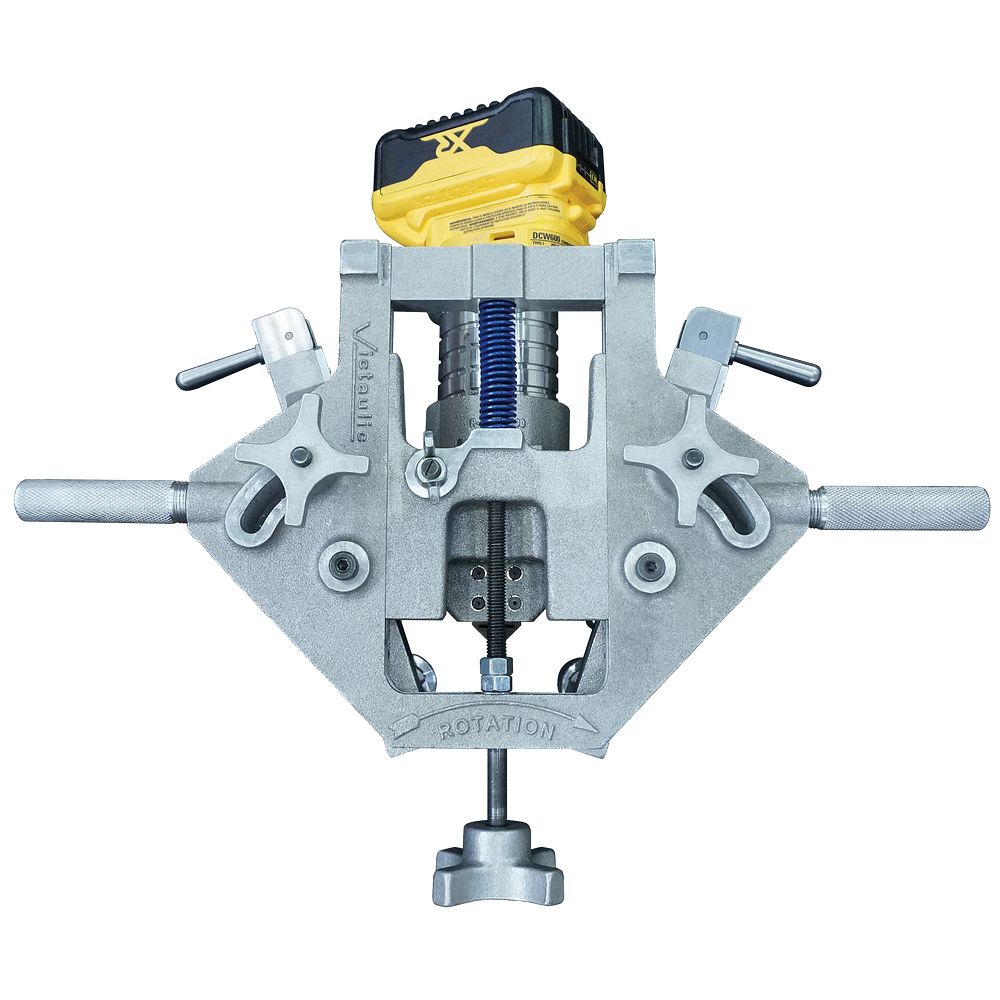

RG5200i Intelligent Roll Grooving Tool

|

|

|

CTH-01 Small 10-Ton Hydraulic Tool

|

|

|

Victaulic Aquamine™ APG Grooving Tool

|

|

|

Power Mule II Tool Power Drive

|

|

|

HCT904 Hole Cutting Tool

|

|

|

CG3100, CG3300, CG3500 Cut Grooving Tools

CG3000 |

|

|

VE872 Roll Grooving Tool

|

|

|

VE226 Power Drive Kit

|

|

|

||

|

PT100A, PT101, PT102A Pipe Diameter Tapes

|

|

|

RG1 Manual Roll Grooving Tool

|

|

|

RG1210 OGS-200 Roll Grooving Tool

|

|

|

RG2910 Roll Grooving Tool

|

|

|

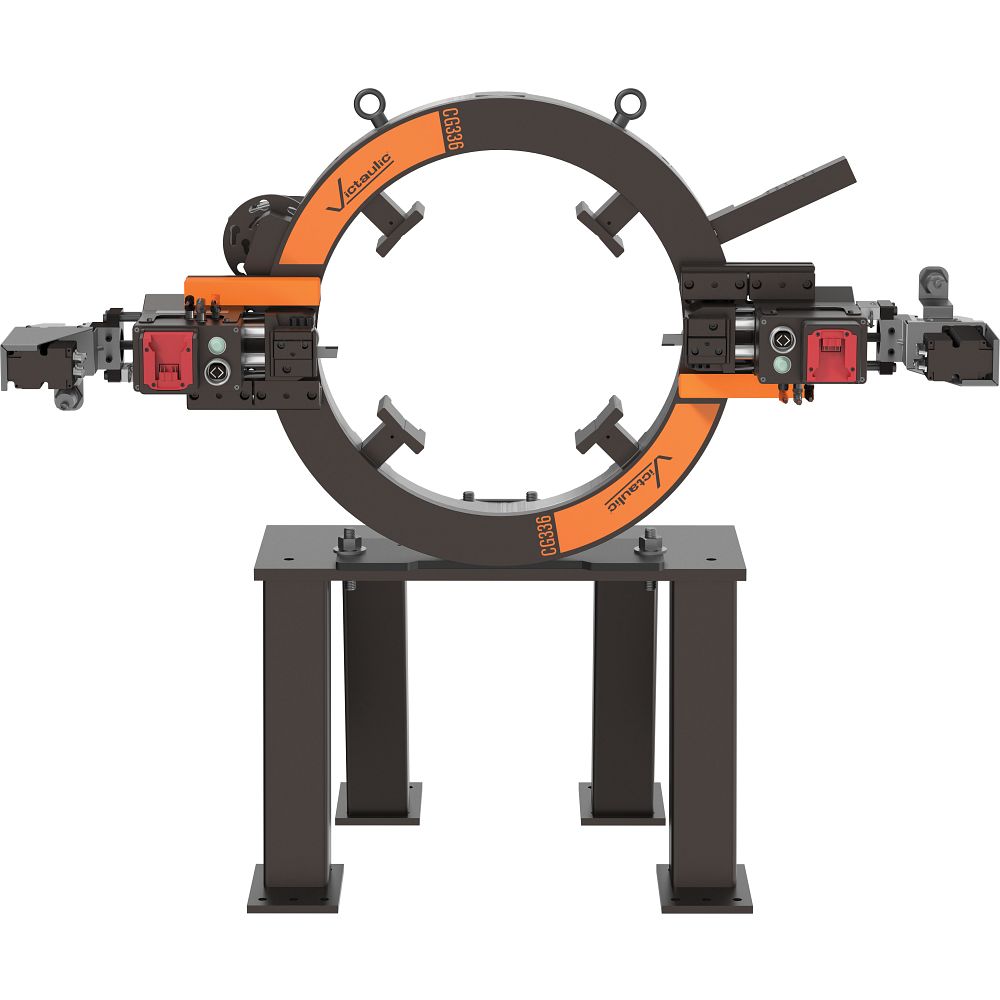

CG336 Portable Cut Grooving Tool• Grooving Capability: 3-36" AWWA ductile iron pipe • Modular field fabrication cut grooving tool • Designed to simultaneously square cut and groove ductile iron pipe ends • Hands-free operation with auto-feed cutting and grooving bits and safety foot switch • External mounting and drive action designed for use with all coating and lining types • Power Requirements: 120 V, 50 – 60 Hz, 20 Amp |

|

|

RG2300 Combo Roll Grooving Tool

|

|

|

RG3400 Roll Grooving Tool

|

PIPE END PREPARATION TOOL DOWNLOADS

- All Resources

- Submittals

- Manuals

| Resource | Number | Downloads | Collection |

|---|---|---|---|

| VE460 Shop Fabrication Roll Grooving Tool Tool Manual | TM-VE460 |

|

|

| HCT904 Tool Manual | TM-HCT904 |

|

|

| VG412 Orbital Cut Grooving Tool Tool Manual | TM-VG412 |

|

|

| VG824 Vic-Adjustable Cut Grooving Tool Manual | TM-VG824_VG828 |

|

|

| Cut Grooving Tool for Advanced Groove System (AGS™) VG828 Tool Manual | TM-VG824_VG828_ADD |

|

|

| VE450FSD Roll Groover Tool Manual | TM-VE450FSD |

|

|

| VE268 Shop Fabrication Roll Grooving Tool Tool Manual | TM-VE268 |

|

|

| VE270 and Style VE271 Roll Grooving Tools Tool Manual | TM-VE270-271FSD |

|

|

| VE272SFS Field Fabrication Roll Grooving Tool Tool Manual | TM-VE272SFS |

|

|

| VE106 Field Fabrication Roll Grooving Tool Tool Manual | TM-VE106 |

|

|

| VE12/VE12S Field Portable Roll Grooving Tool Tool Manual | TM-VE12 |

|

|

| VE206 Portable Roll Grooving Tool Tool Manual | TM-VE206 |

|

|

| Groove-In-Place Tool Manual | TM-VE26 |

|

|

| HCT908 Hole Cutting Tool Tool Manual | TM-HCT908 |

|

|

| VE226 Field Portable Roll Grooving Tool Operating Instructions | VE226 |

|

|

| Style VG28 and VG28GD Cut Grooving Tool User Guide | VG28 |

|

|

| Style VE436MC Roll Grooving Tool Repair Parts Manual | RP-VE436MC |

|

|

| Style VE416FS Roll Grooving Tool Repair Parts Manual | RP-VE416FS_FSD |

|

|

| VE436MC Roll Grooving Tool Slide Upgrade Kit Repair Parts Manual | RP-VE436MC_KIT |

|

|

| VE450FSD Roll Grooving Tool Repair Parts Manual | RP-VE450FSD |

|

|

| VE46 Field Portable Roll Grooving Tool Groove In Place Repair Parts | RP-VE46 |

|

|

| VE206 Portable Roll Grooving Tool Repair Parts Manual | RP-VE206 |

|

|

| VE226 Field Portable Roll Grooving Tool Repair Parts Manual | RP-VE226 |

|

|

| VE270FSD Roll Grooving Tool Repair Parts Manual | RP-270FSD |

|

|

| VE12 Roll Grooving Tool Repair Parts Manual | RP-VE12 |

|

|

| Pipe Preparation Tools Submittal | 24.01 |

|

|

| RG5200i Roll Grooving Tool Submittal | 24.05 |

|

|

| Vic-Groover Cut Grooving Tool Operating Instructions | TM-VG1 |

|

|

| CG1100 Cut Grooving Tool Repair Parts | RP-CG1000 |

|

|

| VE414MC Roll Grooving Tool Repair Parts Manual | RP-VE414MC |

|

|

| VE268 Roll Grooving Tool Repair Parts Manual | RP-VE268 |

|

|

| RG1 IGS Roll Grooving Tool Repair Parts Manual | RP-RG1 |

|

|

| RG1210 OGS-200 Roll Grooving Tool Submittal | 24.14 |

|

|

| RG1210 Roll Grooving Tool Operating and Maintenance Instructions Manual | TM-RG1210 |

|

|

| RG1210 OGS-200 Roll Grooving Tool Repair Parts Manual | RP-RG1210 |

|

|

| RG1 IGS Roll Grooving Tool Operating and Maintenance Instructions Manual | TM-RG1 |

|

|

| RG2910 Roll Grooving Tool Submittal | 24.21 |

|

|

| RG2910 Roll Grooving Tool Operating and Maintenance Instructions Manual | TM-RG2910 |

|