Posted on May 20, 2020

History of the Groove

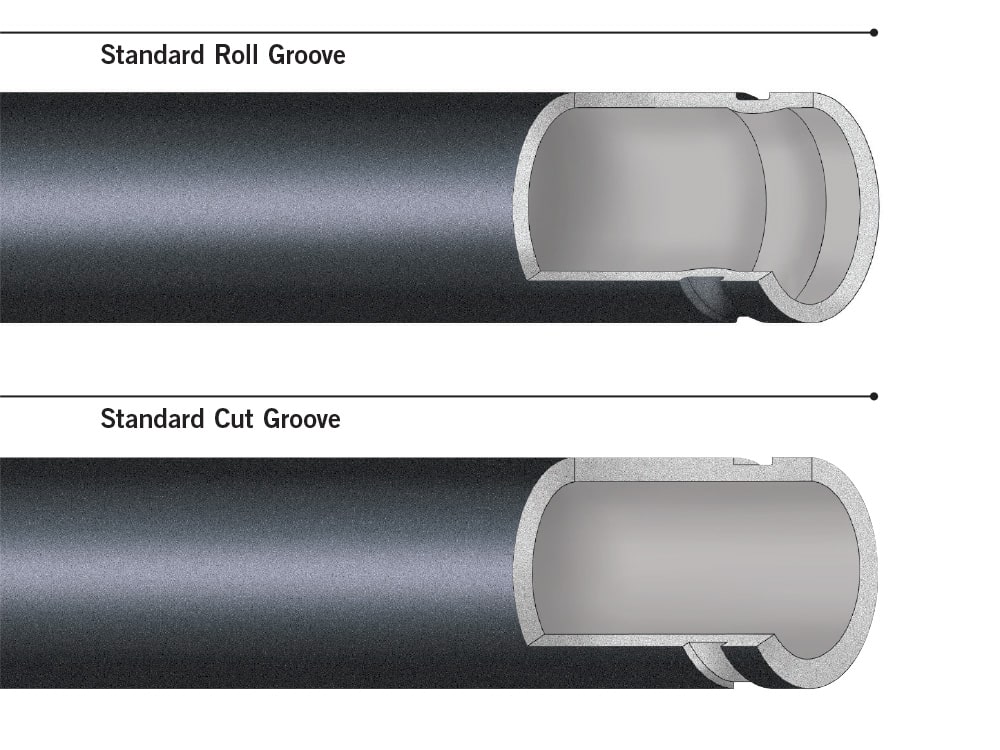

In 1919, Victaulic revolutionized the pipe joining industry with the invention of the mechanical coupling. And while coupling technology has evolved beyond the original Victaulic mechanical joint, the basics behind pipe grooving have stood the test of time. With the original Victaulic Coupling the pipe was cut grooved. When performing a cut groove, pipe material is physically removed from the outside diameter of the pipe, effectively cutting a groove into the pipe, which can then be attached to either side of a grooved coupling.

In the 1950s, Victaulic revolutionized the industry once again with the invention of roll pipe grooving. When performing a roll groove, a pipe is cold formed to create a circular and comprehensive “dimple” in the pipe, creating a groove without removing any pipe material. This new method was critical in moving the industry forward as it increases the speed capability of the groover immensely, with little to no clean up compared to the cut grooving process.

Roll Groove

Roughly 90 percent of pipes grooved today utilize roll grooving technology due to the ease of the grooving process while maintaining optimal joint performance. The pipe can be roll grooved in 30 to 40 seconds per square inch compared to one minute per inch using a cut groove. The roll grooving process also removes the need for cutting oil and the hassle of cleaning up the metal shavings that are removed from the pipe during the cut grooving process.

Roll Groove Pipe Animation

Cut Groove

While roll grooving is very popular, the tried and true cut groove provides very useful in many situations. For example, if the pipe wall is too thick-cut grooving the pipe will provide a more reliable groove. Or if the pipe is internally lined or coated, cut grooving is recommended to keep the integrity of the lining and coating. Even the pipe material can dictate the groove style, some material of pipe must be cut grooved. Cut grooves provide additional engineering advantages, offering twice as much built-in movement compared to roll grooved pipe ends. Regardless if you choose to roll groove or cut groove, Victaulic offers a solution to your pipe joining needs, with the confidence of 100 years of innovation behind it. For more information about grooved technology visit the Victaulic website.

Cut Groove Pipe Animation